- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A composite phase change material (PCM) was studied for thermal energy storage.

• The PCM consisted of high density polyethylene and carbon graphite.

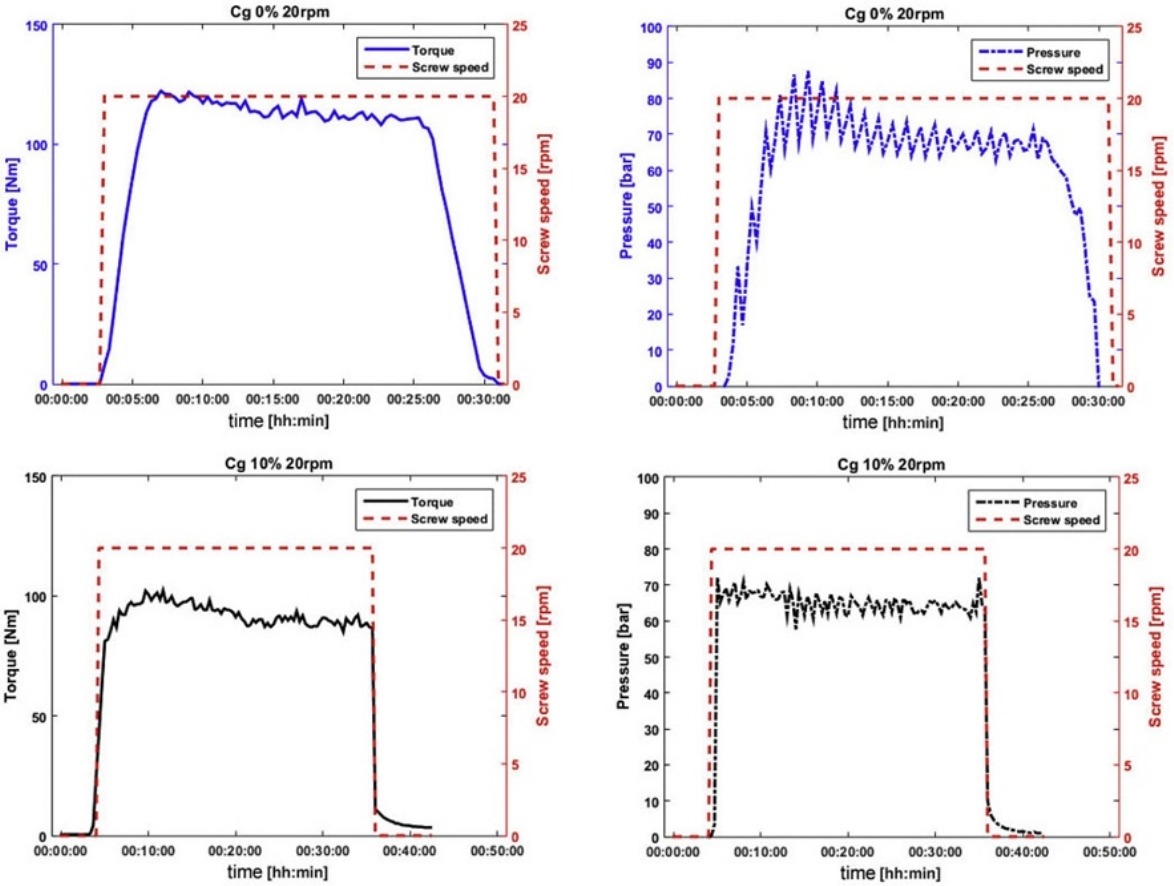

• A single screw extruder was used for continuous manufacturing of the composite PCM modules.

• An enhancement of ∼70% in thermal diffusivity of the composite PCM was demonstrated.

• Linkage between extrusion parameters and PCM thermophysical properties was elucidated.

Thermal energy storage (TES) has the potential to facilitate the deployment of renewable energy through addressing the demand-supply mismatch, ultimately leading to the decarbonisation of heat supply. Among the TES technologies, latent heat based TES with composite phase change materials (PCMs) has shown great potential, which has attracted significant attention in recent years. However, large scale and reliable manufacturing methods for composite PCMs are still largely lacking. Here, we present a study aimed to develop, for the first time, an extrusion process capable of fabricating high density polyethylene based graphite PCM composites at a high throughput and with enhanced thermal properties. The PCM composites were fabricated under different extrusion process parameters and characterized for their thermo-physical properties by multiple techniques including differential scanning calorimetry, thermal gravitational analyzer, and Fourier transform infrared spectroscopy. The results show that the extrusion process has the potential to fabricate PCM composite bars in a continuous fashion with a manufacturing throughput higher than traditional method; the fabricated PCM composites show enhanced properties (e.g. up to +70% increase in thermal diffusivity); and there is a clear link between extrusion process parameters and PCMs properties. Microstructural analyses show a more homogeneous structure with a lower extrusion speed; whereas a high extrusion speed gives a more microscopically heterogeneous structure with visible graphite agglomerates distributed relatively homogeneous macroscopically; and a higher graphite content gives a larger agglomerate size. The results of this work suggest that the elucidation of composition–process–property relationships is crucial: for a given formulation (composition), only through fine tuning of high throughput manufacturing process can make it possible to achieve the desired performance of the PCM composites.