- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

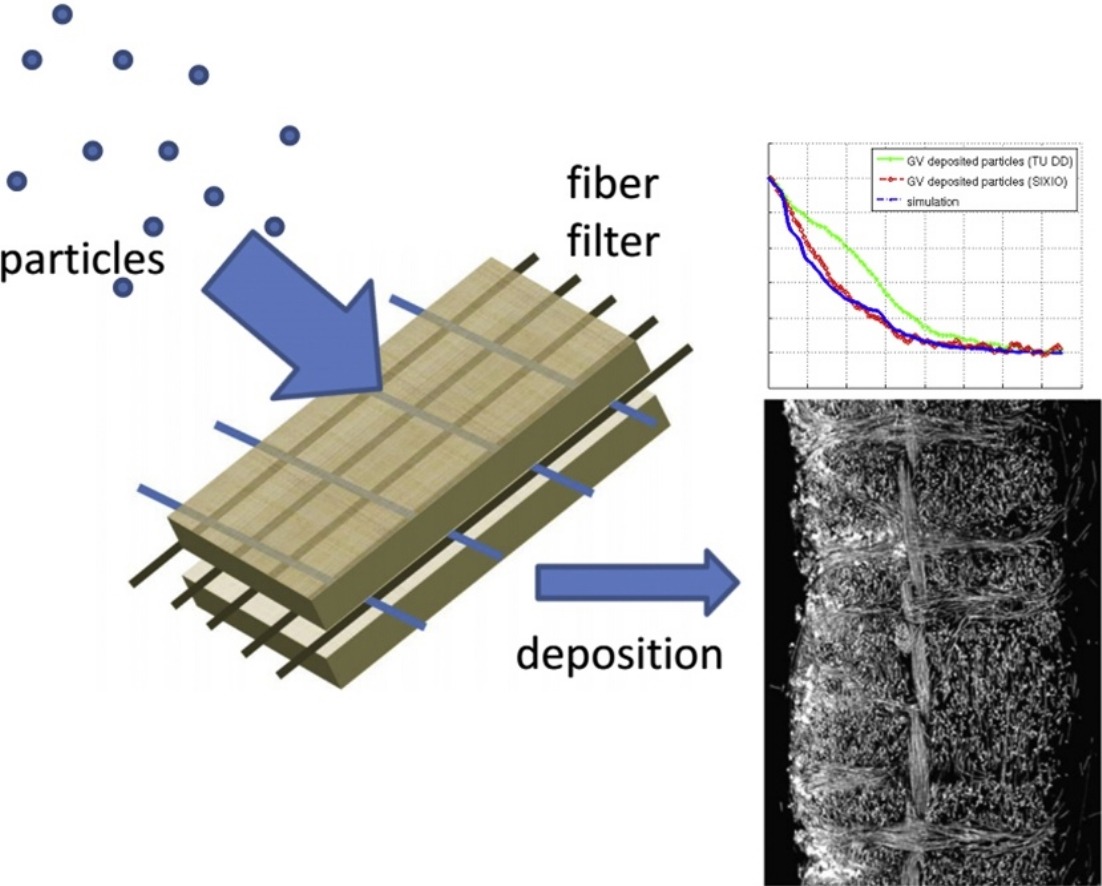

• Particle penetration and separation in fiber filters were analyzed by μ-CT.

• Coupled DEM–CFD simulations were made for filter structures with different fiber arrangements.

• Particle deposition within fiber filters was simulated employing a mesh-morphing procedure.

• The simulated and experimentally evaluated penetration depths were in good agreement.

• Dynamic particle penetration depth and filtration efficiency were evaluated.

Particle separation from gases is an important unit operation in manifold industrial applications, such as those conducted in environmental protection. For analysis of particle penetration and separation in fiber filters, standard dust particles (Al2O3) were loaded in the gas flow of a filter test facility and deposited within new and uncharged fiber filters. The loaded filters were analyzed by micro-computer tomography and scanning electron microscopy. Three-dimensional tomograms of the samples show an exponential decay of the penetration depth of the particles. This dependency is confirmed by simulations conducted using the discrete element method coupled with computational fluid dynamics within unloaded and loaded fiber structures. Microscale processes of particle separation at the fibers as well as the filtration efficiency and time-dependent filtering process are derived from the simulations. Local particle clustering in the filter medium and partial filter clogging are thus identified.