- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A novel model for fluidization of a binary mixture of biomass and sand was developed.

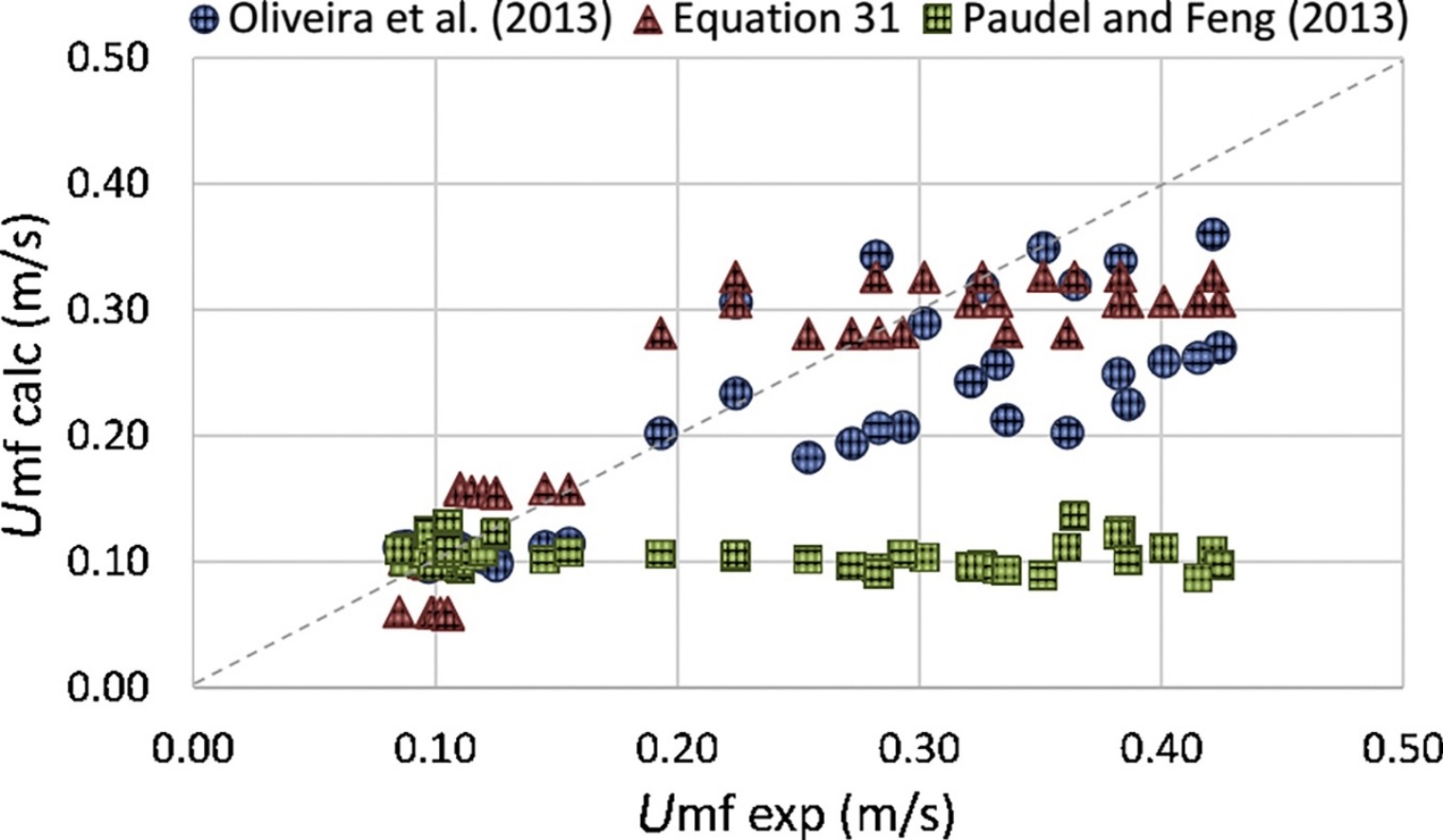

• Discrepancy between measured and model predicted Umf was calculated and compared.

• Discrepancies for sisal residue were 15.32% (literature) and 12.23% (new model).

• Discrepancies for other biomasses were 17.4% (literature) and 20.5% (new model).

The influence of different factors on the fluidization of a binary mixture of sisal residue and sand was investigated. The particle sizes of the sand and sisal residue were varied from 0.2 to 0.8 mm and the biomass mass fractions from 2% to 9%. Some segregation was noted, and a significant relationship was found among the final fluidization velocity (Uff), the biomass and sand sizes, and the biomass mass fraction. A novel model was developed for predicting Uff, leading to an average discrepancy of 12.69% between the measured and predicted Uff compared with the best match of 15.32% when using a model from a previous paper. The new model was applied to data from studies using other biomass and a broad range of particle characteristics. The average divergences from measured values when using the new model were 7.9% for corn cob and walnut shell, and 20.5% for sweet sorghum bagasse, tobacco residue, and soy hulls. These were superior to the values derived using other models. Our results confirm the accuracy of the model developed in this work and show that it represents a viable alternative way to calculate Uff for a binary mixture of sand and biomass.