- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• SnO2/NiO composite oxides were synthesized by microwave-assisted liquid phase deposition (MLPD).

• MLPD shortened the deposition time and improved the specific surface area of SnO2/NiO powders.

• When the molar ratio of Ni2+ to Sn4+ was 0.1, the gas response to 1000 ppm ethanol reached 85.

• Improved gas sensing may be attributed to the strengthening of P–N heterojunction.

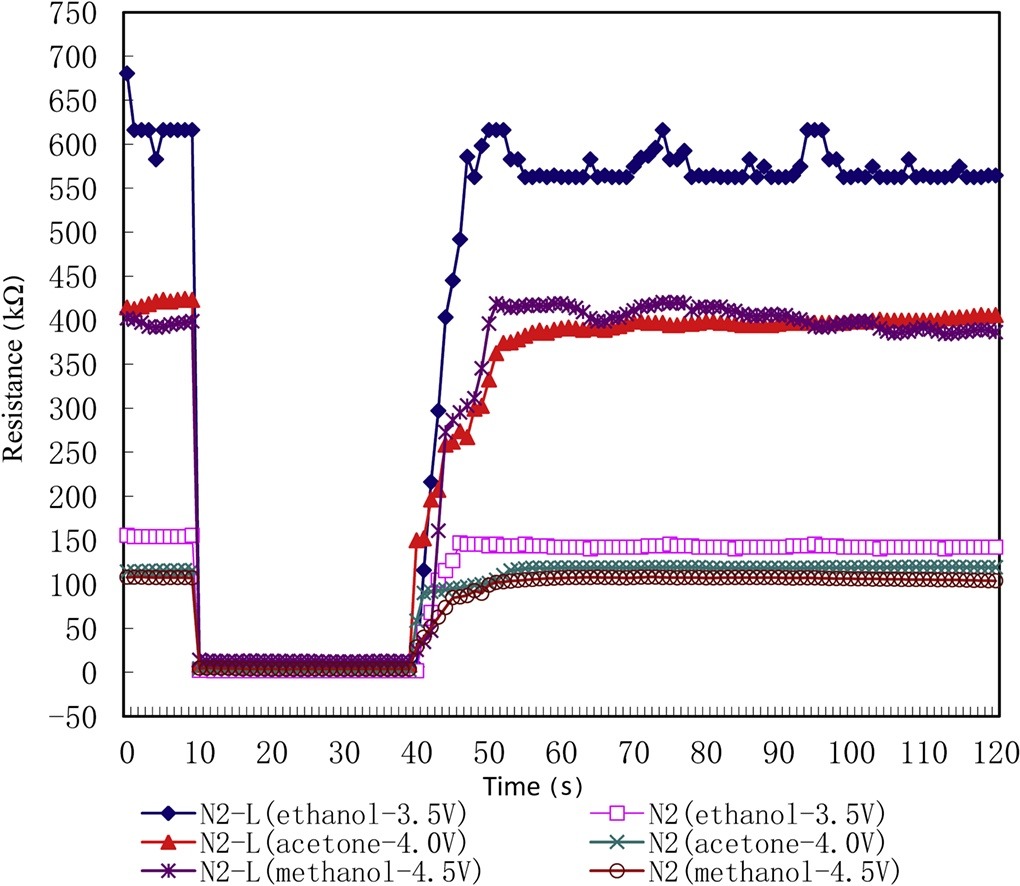

We synthesized SnO2/NiO composite oxides by microwave-assisted liquid phase deposition to improve their surface physico-chemical properties and gas-sensing selectivity, and we investigated how the molar ratio of Ni2+ to Sn4+ and the microwave power affected their gas-sensing performance. The microstructure, surface physico-chemical states, and morphology of the samples were characterized by X-ray diffraction, X-ray photoelectron spectroscopy, and scanning electron microscopy, respectively. Nitrogen adsorption–desorption isotherms were used to characterize the specific surface areas of the samples. Our results showed that microwave-assisted liquid phase deposition increased the surface-adsorbed oxygen content and the specific surface area of the SnO2/NiO composite oxide from about 22 to 120 m2/g. When the molar ratio of Ni2+ to Sn4+ was 0.1, the gas response to 1000 ppm ethanol gas reached 84.7 at a lower working voltage of 3.5 V. However, the optimum working voltages for methanol and acetone gas were 4.5 and 4.0 V, respectively. Thus, a new method was found to improve the selectivity of the gas sensor. Moreover, at a working voltage of 4.0 V, the gas response of a SnO2/NiO gas sensor synthesized by microwave-assisted liquid phase deposition with the optimum radiation power of 450 W to 1000 ppm acetone gas was 49.7, twice that of a sensor synthesized by traditional liquid phase deposition.