- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Effects of reduction conditions on carbon deposition of iron ore fines was investigated.

• Addition of H2 in CO–CO2 in pre-reduction step promoted the formation of graphite filaments.

• Graphite could inhibit the formation of fibrous iron and decrease the surface viscosity.

• Graphite was more reactive than Fe3C during gasification and solid-state reduction.

• Carbon deposits acted as efficient reductant for the reduction of FeO to Fe above 950 °C.

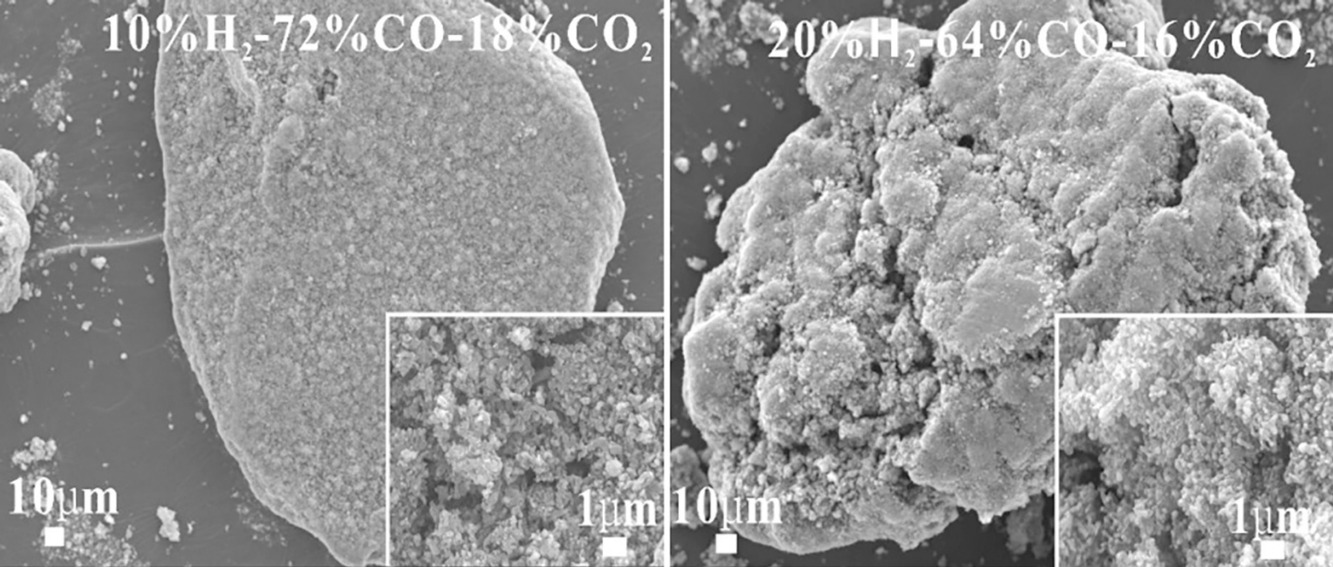

The influence of reduction conditions on carbon deposition during fluidized-bed pre-reduction of iron ore fines was investigated experimentally. The results showed that reduction temperature and the composition of reducing gases had a significant effect on the rate of carbon deposition and the type of carbon deposits (graphite and Fe3C). Low reduction temperature, high CO content, and addition of H2 favored the deposition of carbon, especially graphite. The reduction conditions also significantly affected the surface morphology of the as-reduced iron ore fines. As the amount of deposited graphite increased, the formation of fibrous iron disappeared and graphite filaments were observed. The pre-reduced iron ore fines were further fluidized in pure CO at 850 °C for final reduction. The results showed that graphite could suppress the formation of fibrous iron and decrease the surface viscosity, thereby inhibiting agglomeration during the final high-temperature reduction stage. Reactions that consume the deposited carbon during the final high-temperature reduction were identified and graphite was shown to be more reactive than Fe3C. To enhance the application of fluidization technology in producing sponge iron, a novel solid-state high-temperature reduction method via deposited carbon was proposed and demonstrated to be feasible.