- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

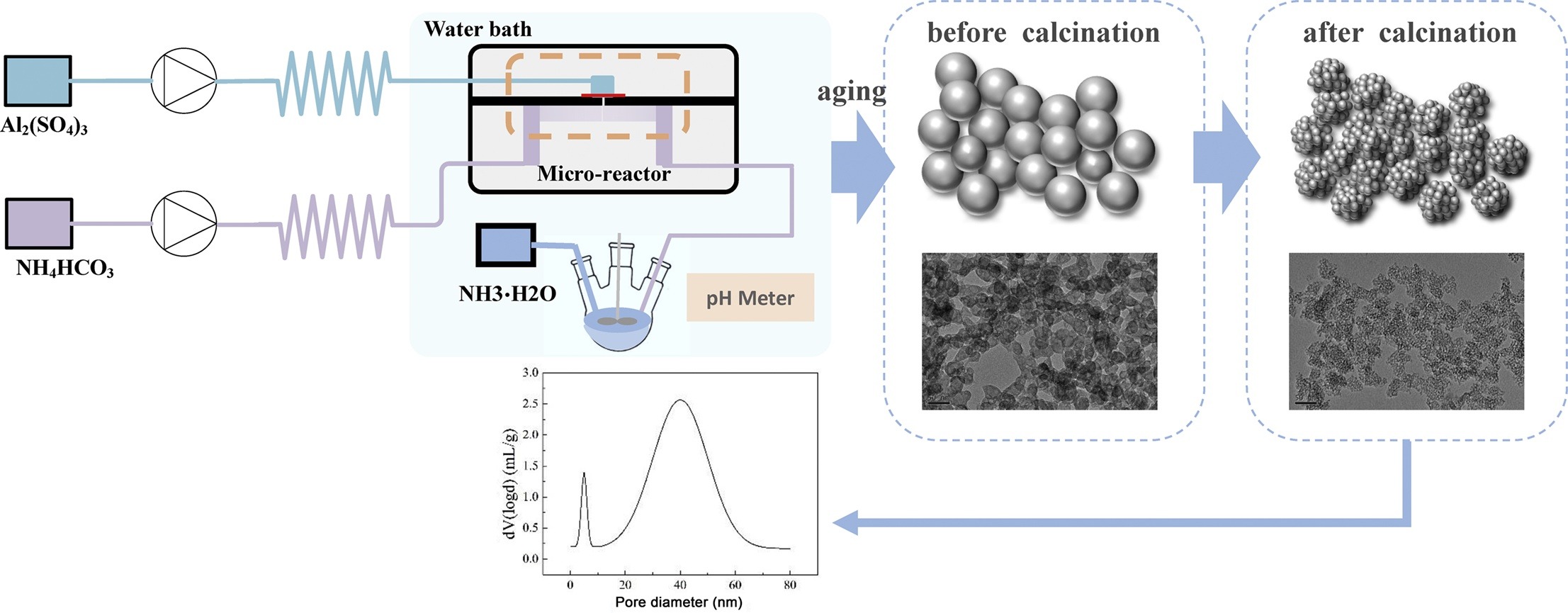

• γ-Alumina nanoparticles were prepared using a membrane dispersion microreactor.

• γ-Alumina was obtained with a specific surface area of 504.7 m2/g, maximum pore volume of 1.76 mL/g.

• The γ-alumina nanoparticles showed a bimodal pore size distribution.

In this paper, we present a new method for preparing γ-alumina nanoparticles with a bimodal pore size distribution by using an efficiently mixing membrane dispersion microreactor. NH4HCO3 and Al2(SO4)3∙18H2O were reacted under vigorous mixing to give an ammonium aluminum carbonate hydroxide (AACH) precursor. γ-Alumina was obtained by calcination of AACH at 550 °C for 6 h. The effects of NH4HCO3 concentration, pH during aging, and reaction temperature were investigated. The mechanism of bimodal pore formation was clarified. The results showed that large pores (10–100 nm) were mainly formed in the reactor and during aging, and small pores (0–10 nm) were mainly formed during calcination. When the concentration of NH4HCO3 was 1.5 mol/L, the aging pH was 9.2, and the reaction temperature was 80 °C, γ-alumina with a specific surface area of 504.7 m2/g and pore volume of 1.76 mL/g was obtained. The average size of the large pores was about 30 nm, and the average size of the small pores was about 4 nm.