- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

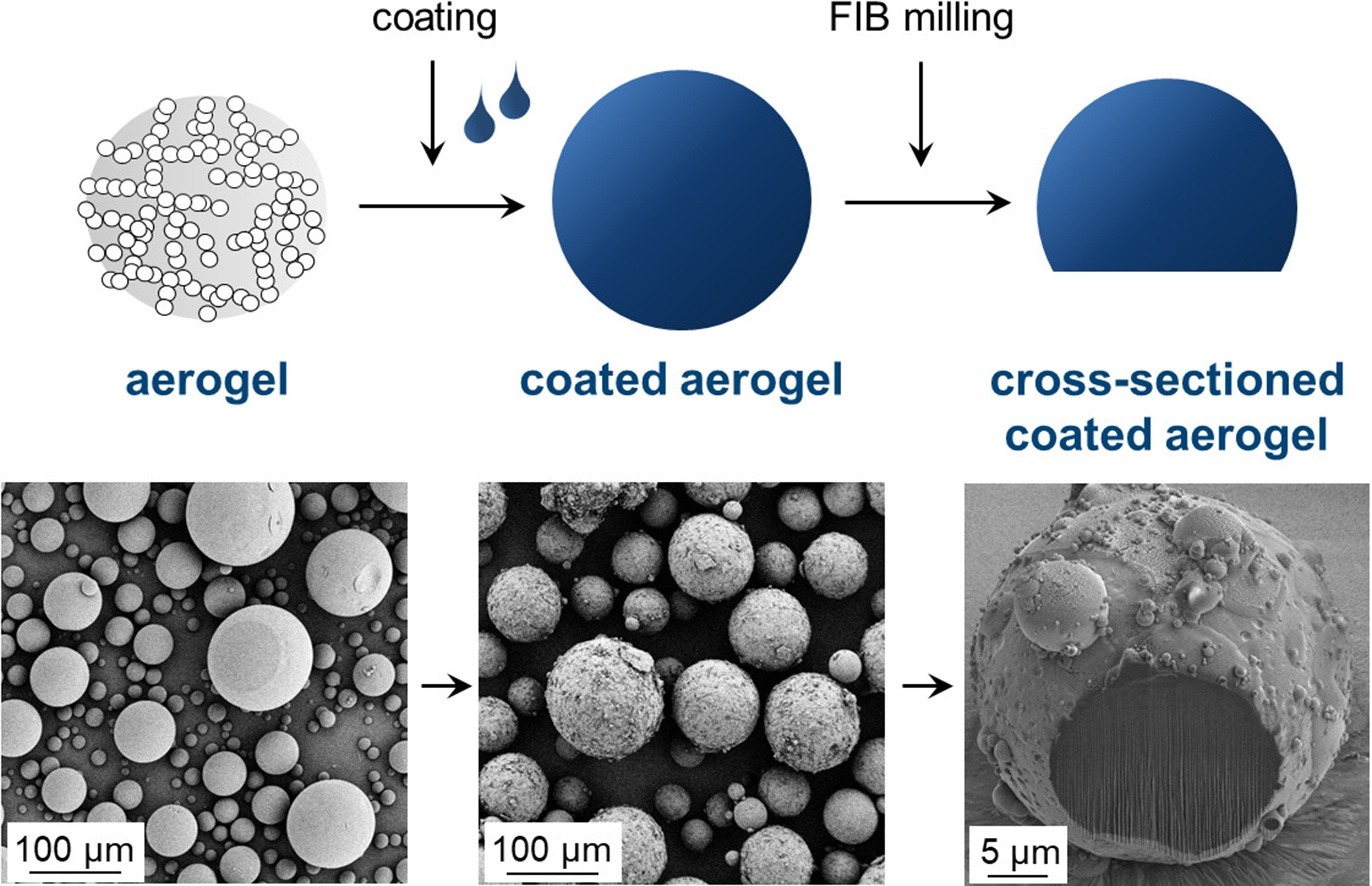

• Light and highly porous aerogel microspheres were coated in dilute spouting regime.

• The coated microparticles were cross-sectioned using focused ion beam.

• Film thickness of cross-sectioned coated microparticles was precisely measured.

• Successful and uniform coating with layer thickness of around 1 μm was achieved.

A novel technique for the measurement of the coating layer thickness of fine particles was developed in this work based on cross-sectioning of micrometre-sized single coated particles using focused ion beam (FIB) milling. This technique was tested on two batches of aerogel particles coated with thin coatings in a spouted bed. The FIB milling procedure consisted of two steps. First, the desired part of the coated particle was removed using a high ion beam current. The resulting cross-sectioned area was then polished using a lower ion beam current to make the cross-section clearly visible. The FIB milling process was controlled with simultaneous scanning electron microscopy (SEM). Afterwards, the coating layer thickness was evaluated using the SEM images.

The coating layer was successfully applied on the porous aerogel microparticles in the spouted bed. The coating uniformity of the highly porous particles increased with increasing sprayed coating solution amount, with up to 91% of the particle pores being covered. The FIB-cross-sectioning technique using an ion beam of 2.50 nA for the first milling and 0.43 nA for polishing of the surface resulted in successful generation of cross-sections of representative particles with a visible particle core and coating layer. A coating layer thickness of approximately 700 nm was achieved on particles with sizes of below 45 μm.