- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

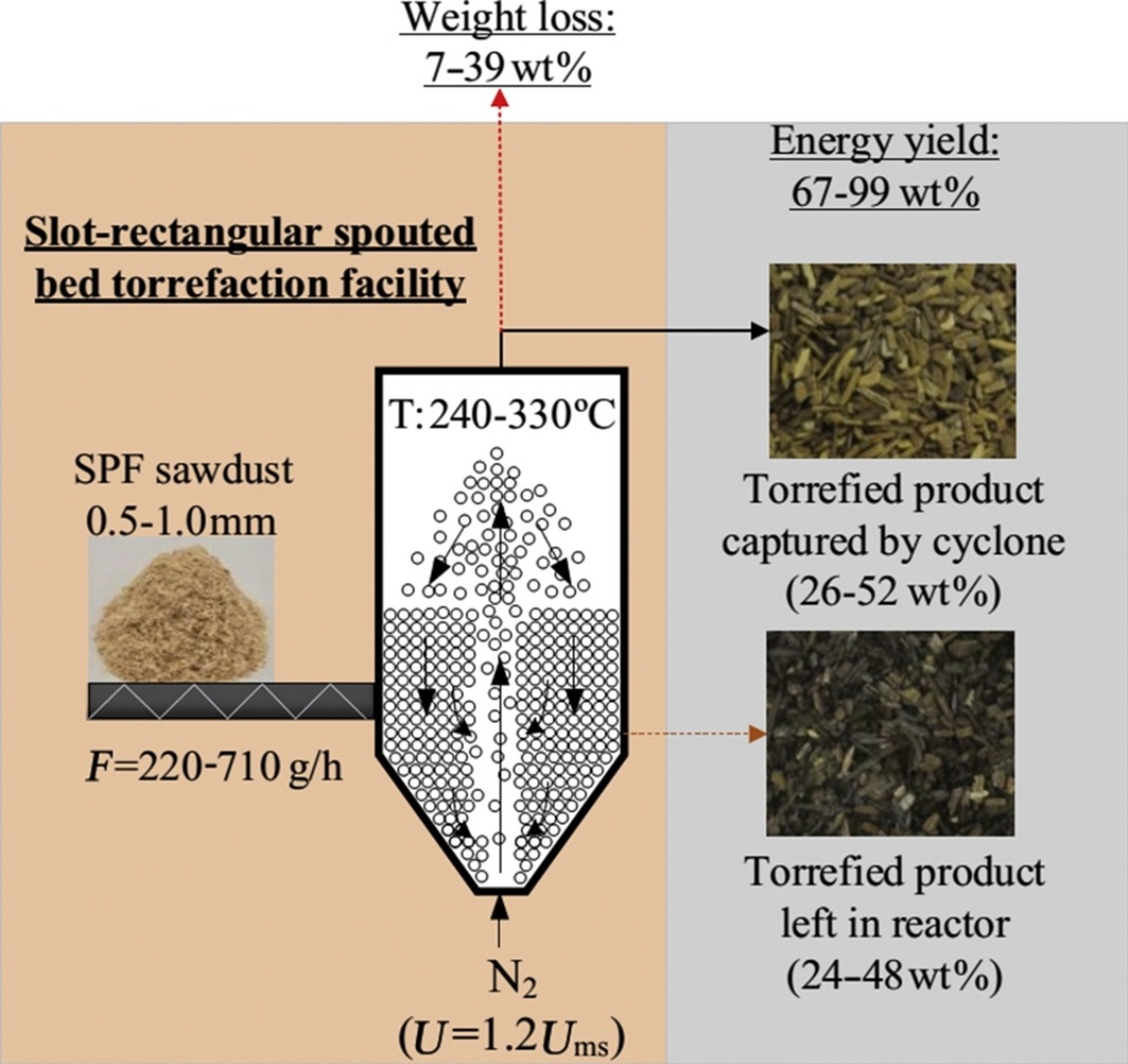

• A slot-rectangular spouted bed torrefaction reactor was designed and characterized.

• Temperature and biomass feed rate affected spruce–pine–fir sawdust torrefaction.

• Weight loss and energy yield of the torrefied sawdust ranged from 7% to 39% and 67% to 99%.

• Biomass particle size decreased markedly as a result of torrefaction.

Sawdust was subjected to torrefaction in a "semi-batch" slot-rectangular spouted bed (SRSB) reactor at temperatures from 240 to 330 °C and biomass feed rates from 220 to 710 g/h. Stable spouting of the sawdust was achieved in the slot-rectangular spouted bed, although the pressure drop across the reactor was observed to oscillate. Compared to the biomass feed rate, the temperature had a greater effect on the biomass weight loss and energy yield. Increases in temperature were found to promote weight loss of the sawdust while decreasing the energy yield. The main solid product was the torrefied sawdust, which remained in the SRSB reactor and was captured by a cyclone. The ratio of the torrefied biomass removed by the cyclone to the total torrefied biomass increased along with both the feed rate and temperature. After undergoing torrefaction, 6.7%–39.2% of the original sawdust mass was lost while 67.4%–98.7% of its energy was retained. The torrefied sawdust had a higher carbon content but less oxygen, hydrogen and volatiles, along with a greater higher heating value and increased density compared to the raw sawdust. The size of the sawdust particles also decreased markedly during the torrefaction process.