- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

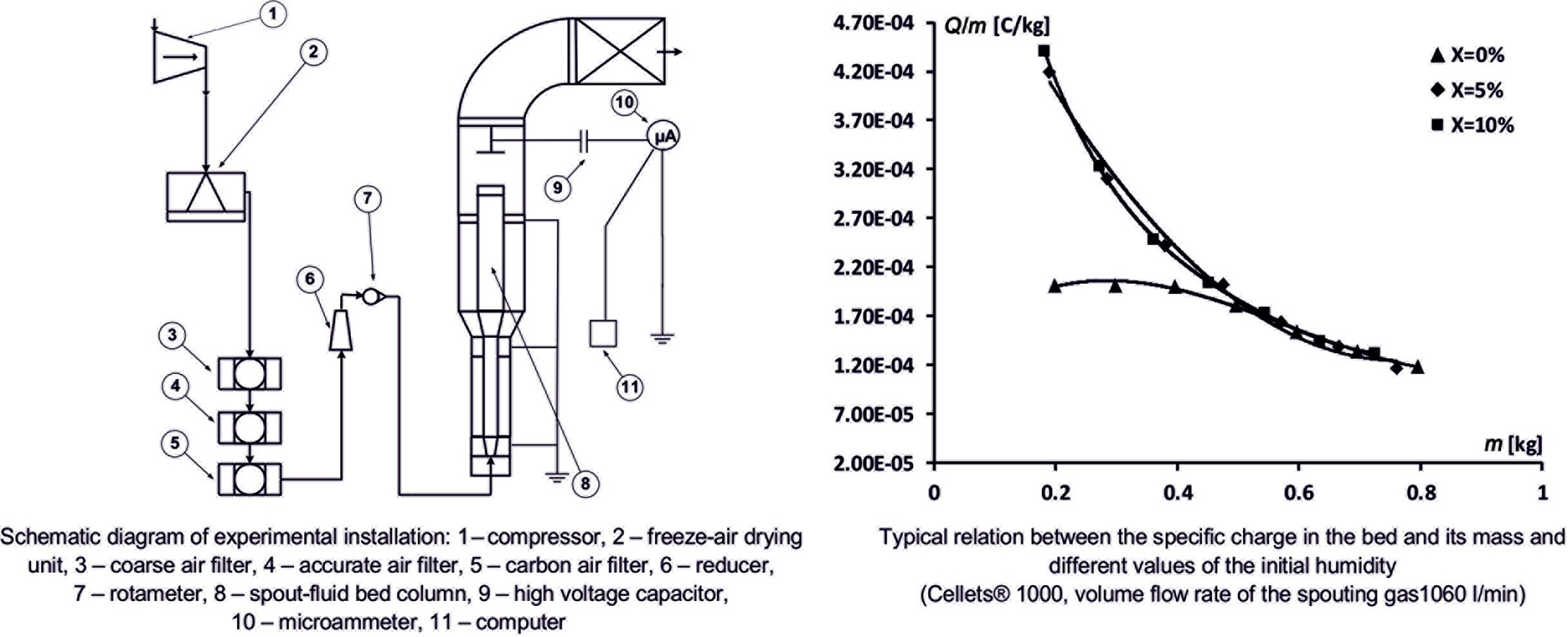

• The values of the electrostatic charge in the modified Wurster apparatus are determined.

• Impact of the process parameters on the electrostatic charge is investigated.

• The electrification of the bed is very intensive.

• The electrostatic charge relatively little depends on tested process variables.

• Such intense electrostatic phenomena can be used in the electrostatic coating process.

The intensity of the electrostatic charge accumulated during the flow of Cellets® particles in a modified Wurster apparatus is investigated in terms of the bed mass, and the initial moisture and velocity of the spouting gas. Particle electrification is proportional to the increase in the velocity of the spouting gas, which is connected with a higher velocity of the cores and the strength of their impact on the walls of the device. The presence of moisture in the bed facilitates electrification, but does not affect circulation, since moisture simultaneously lowers the bed resistance and reduces the relaxation time of particles, leading to rapid discharging if brought into contact with the conducting elements of the apparatus. Therefore, with regard to classic dry-powder coating, the velocity of the spouting gas should be minimized to ensure good circulation, with the particle moisture held at the maximum level admissible for a given product. The investigations show that a unique construction of the apparatus, which brings about an intense natural electrification of the cores, makes it suitable for the electrostatic dry-coating process by means of a high-voltage feeder with the controlled charging of coating powder in the spray nozzle.