- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

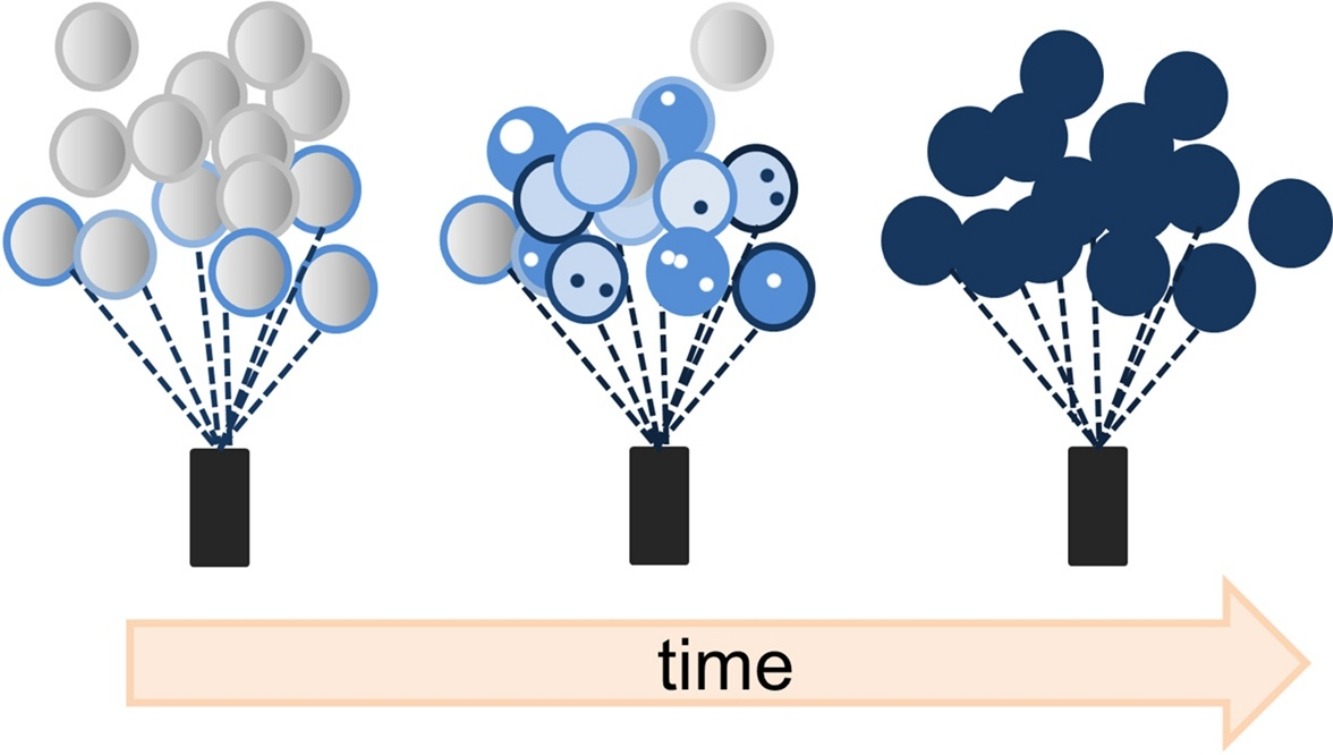

• A new method to quantify the coating progress in a spouted bed was developed.

• Coating progress was tracked with high speed camera and analyzed with digital image analysis.

• The coating quality was estimated via the change in particle brightness.

• Time point of nozzle blockage could be determined from images.

An optical method of experimentally quantifying the coating progress in a laboratory prismatic spouted bed is presented. Microcrystalline cellulose particles with size dp = 0.57 mm are used as core material. Waterborne coating suspensions with methylene blue as a dye are used and sprayed via a two-fluid nozzle in bottom-spray configuration. A high-speed camera with a color filter is positioned in front of the observation window of the three-dimensional plant and records the flow pattern in the process chamber with a certain frequency. With increasing surface coverage, the particles become bluer and darker. The change in brightness is detected by digital image analysis. In the implemented algorithm, the spherical particles are detected, cut from the background and normalized regarding their lighting and area. The detection of coated pixels on the single particles allows the calculation of the coating fraction and coating uniformity after a Kalman filter has been applied to reduce noise. It is shown that the method can be used to determine the time needed to reach the maximum blue value indicating a complete coating of the particle bed. Besides the minimum coating duration, information on the spraying performance (e.g., the time point of a possibly occurring blockage of the nozzle) can be obtained from the data. Two exemplary experiments are presented, showing a connection of the slope of the coating fraction and the uniformity of the coating of the particles in the apparatus that results in the recommendation of a slow liquid injection for obtaining consistent coating layers as desired in many applications.