- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

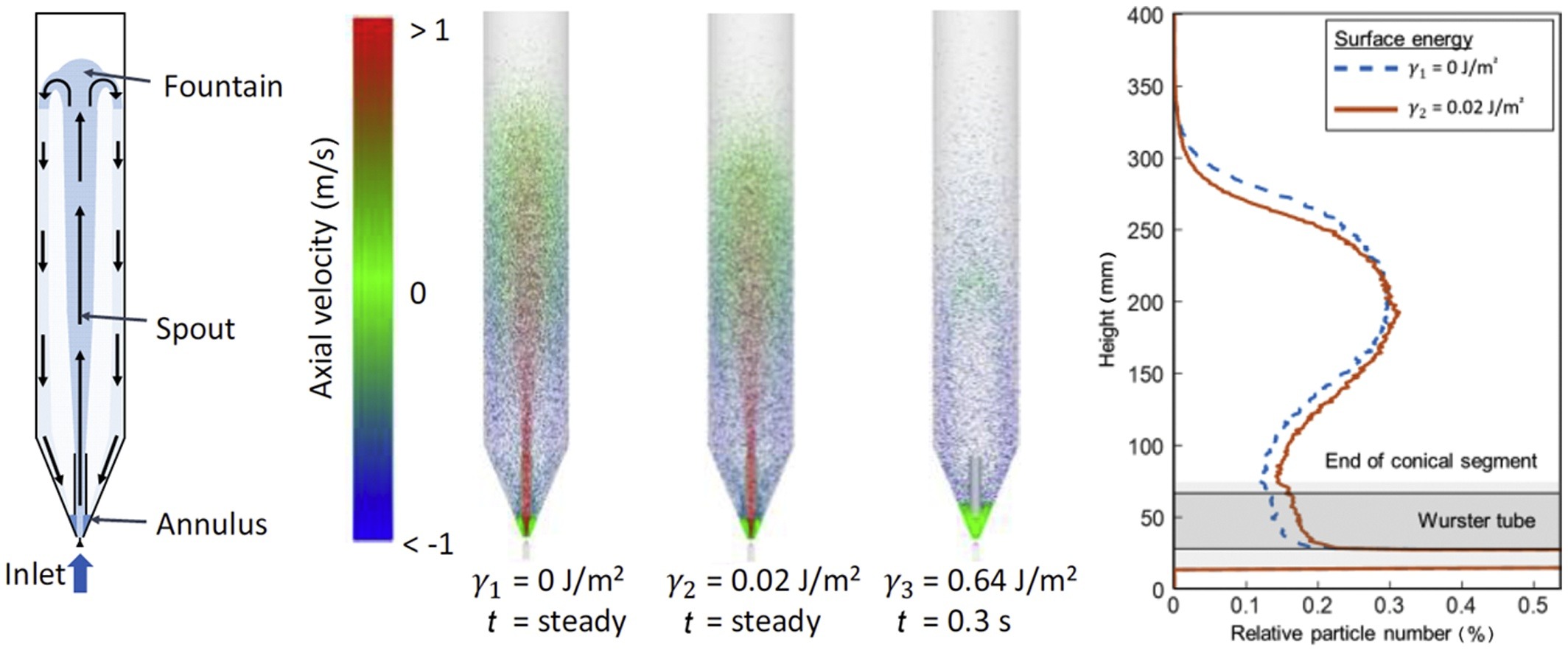

• Fine particle dynamics were simulated in a spouted bed with a Wurster tube using CFD–DEM approach.

• Effect of particle surface energy on particle dynamics was studied in a range of 0–0.02 J/m2.

• Experiments using high-speed camera showed a good agreement to simulated spout shape and height.

• Local particle concentration, velocity and collision number in the spouted bed were analyzed.

• Particles with surface energy of 0.02 J/m2 showed smaller axial velocity and higher spout height.

In this work, a coupled computational fluid dynamics–discrete element method (CFD–DEM) approach was employed to evaluate the spouting behavior of fine, cohesive powders in a cylindrical spouted bed with a conical base and equipped with a Wurster tube. The particle and gas dynamics inside the apparatus were simulated with 1.7 million spherical ZrO2 particles with a particle size of 100 μm. For an accurate prediction of the interactions of cohesive particles in the spouted bed, the adhesion forces according to JKR theory were included in the Hertz–Tsuji contact model. The surface energy of the particles was varied over a wide range to determine the effect of the adhesion on the spouting (the fountain shape and maximum height as well as the distribution of the concentrations and velocities of particles in different zones of the apparatus). A detailed analysis of the collision dynamics was conducted. The spouting behavior of a spouted bed with the same dimensions, particles, and processing parameters was recorded with a high-speed camera. The CFD–DEM simulations showed good agreement with the experimentally captured spouting behavior.