- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

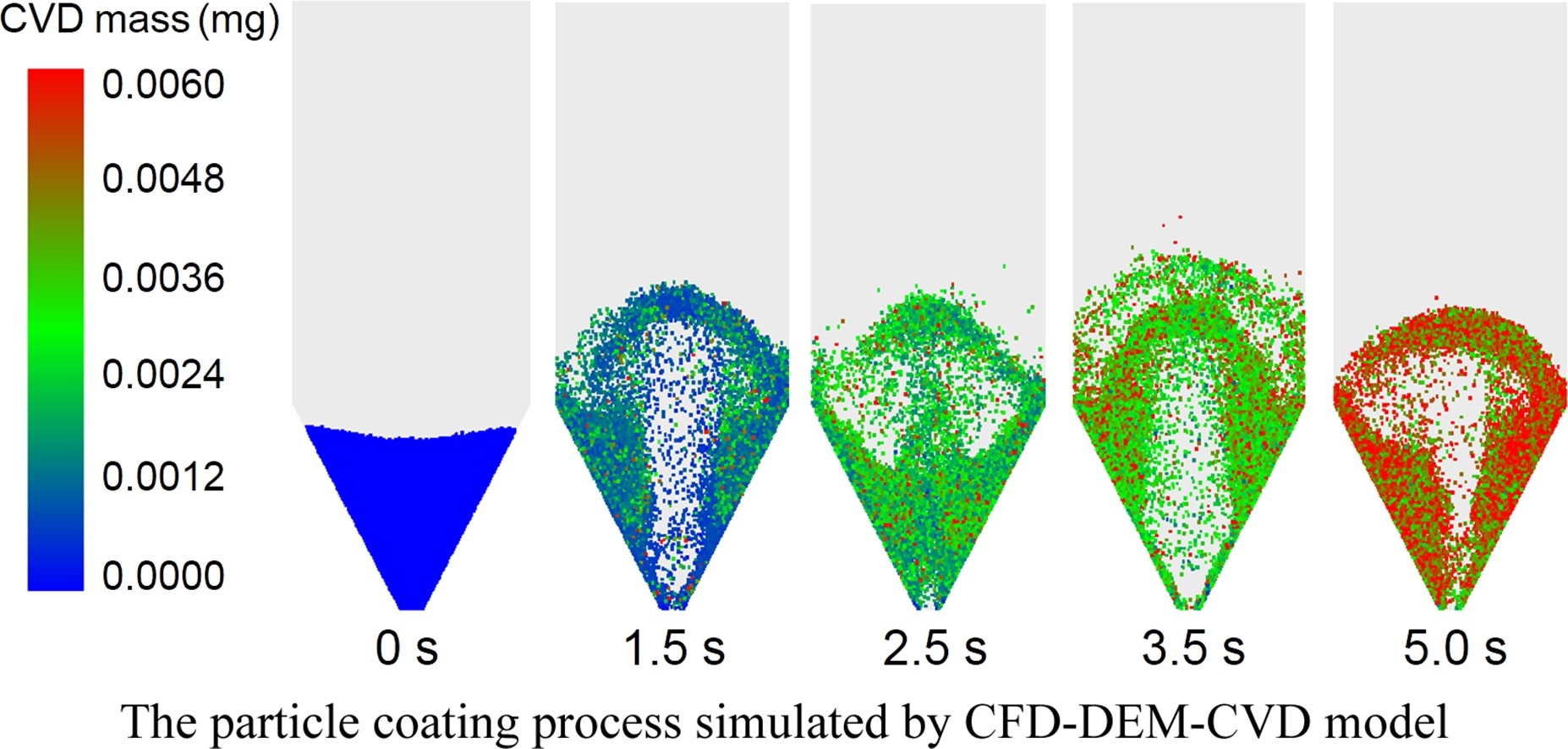

• A coupled CFD–DEM–CVD multi-physical field model for particle-coating simulations was proposed.

• The velocity field, temperature field, concentration field and deposition behavior was simulated.

• Deposition rate and coating efficiency showed opposite tendency with increasing inlet gas velocity.

• The model can provide some guidance for operating conditions and parameters design of spouted bed.

Particle coating is a very important step in many industrial production processes as the particle coating layers may fix surfaces with unique advantages. Given the limitation and disadvantages of the existing simulation methods, a coupled CFD–DEM–CVD multi-physical field model for particle-coating simulations has been established taking into account the velocity field, temperature field, concentration field, and deposition model. In this model, gas behavior and chemical reactions are simulated in the CFD frame based on the conservation laws of mass, momentum, and energy. The particle behavior is simulated in the DEM frame based on the gas–solid interphase force model and contact force model. The deposition behavior is simulated in the CVD frame based on the particle movement–adhesion–deposition model. The coupled model can be implemented in Fluent-EDEM software with their user definition function and application programming interface. The particle coating process involving the pyrolysis of acetylene was investigated, and the effect of bed temperature and inlet gas velocity on deposition rate and coating efficiency were investigated based on the proposed model with adjustable deposition coefficients. Both the average deposition layer mass and the average deposition layer thickness were found to be proportional to the elapsed time and increased at the rate of about 1.05 × 10−2 mg/s and 3.45 × 10−4 mm/s, respectively, setting the inlet gas velocity to 11 m/s and bed temperature to 1680 K. A higher temperature and larger inlet gas velocity lead to a larger deposition rate, but the coating efficiency decreases because of limits imposed by the chemical reaction. At a bed temperature of 1280 K, the average deposition rate is 7.40 × 10−3 mg/s when the inlet gas velocity is set to 11 m/s, which is about double the deposition rate when the inlet gas velocity is set as 5 m/s. The proposed model can provide some guidance for the operating conditions and parameters design of the spouted bed in actual coating settings and can also be further developed as a basic model of mechanisms to integrate detailed information across multiple scales.