- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

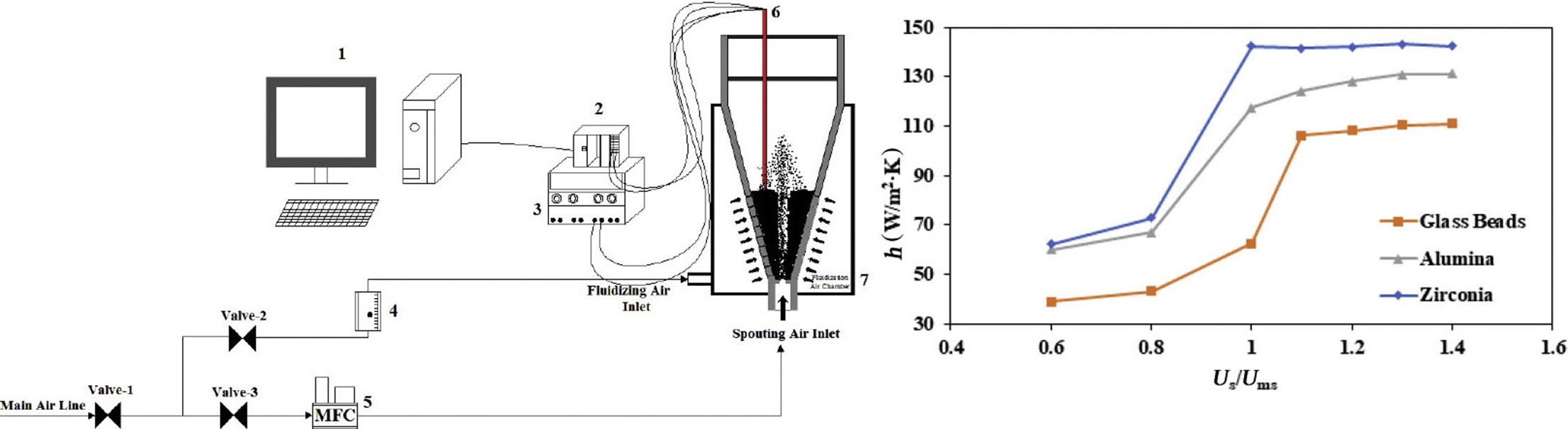

• Bed-to-surface heat transfer experiments were conducted in conical spouted and spout–fluid beds.

• Glass beads, alumina and zirconia particles were used in heat-transfer experiments.

• The appropriate location of a submerged cylindrical heater was the spout–annulus interface.

• A proposed correlation was applicable for predicting average heat transfer coefficient in annulus.

Bed-to-surface heat transfer experiments from a vertically submerged cylindrical surface were conducted in laboratory-scale (Dc = 25 cm) conical spouted and spout–fluid beds at two different conical angles (31° and 66°) in the high particle density range (2500 kg/m3 ≤ ρp ≤ 6000 kg/m3). The effects of the bed design parameters (conical angle and inlet diameter of spouting gas entrance) and operating conditions (static bed height, particle size, density, and spouting and fluidization gas flow rates) on the heat transfer characteristics were investigated in detail. The heat transfer coefficients were shown to be dependent on the density and size of the particles. The minimum stable spouting velocities of the denser and larger particles were higher, which led to higher operational spouting velocities and thereby resulted in higher heat transfer coefficients. The positive effect of increasing the particle diameter on heat transfer was more pronounced in the spout and at the spout–annulus interface, whereas this effect was diminished in the annulus region. The heat transfer coefficient increased with increasing spouting gas velocity up to 1.0Ums–1.1Ums, beyond which no significant change was observed regardless of the particle type. The heat transfer coefficient in the annulus decreased with increasing conical angle because of reduced particle circulation. The spout–fluid operation increased the heat transfer coefficient by a maximum of 10% at the expense of a significant increase of the total gas flow rate. This result was attributed to the inability of the fluidizing gas to penetrate the annulus. An empirical correlation for the average heat transfer coefficient in the annulus was also proposed based on the data obtained in this work.