- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

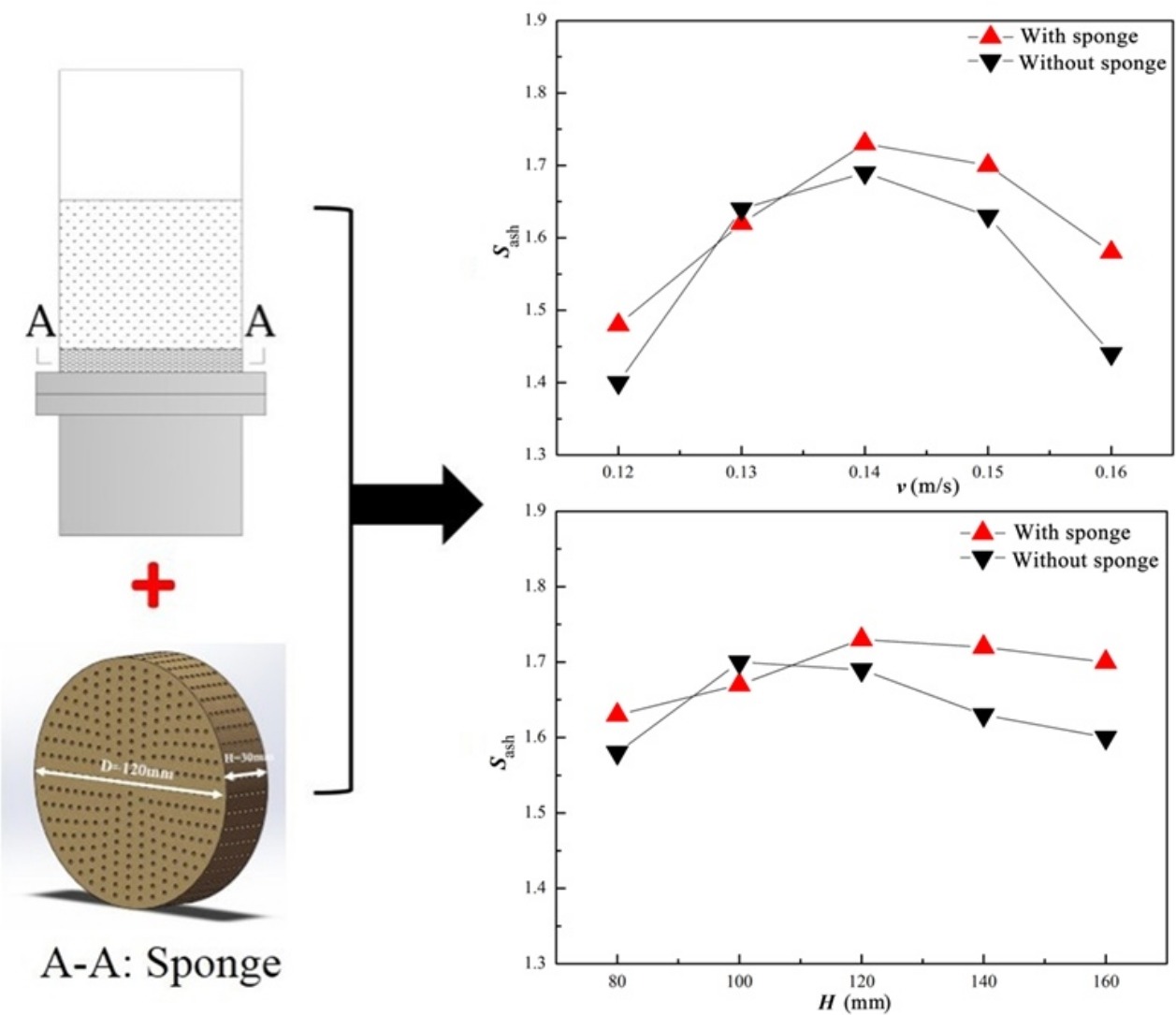

• A gas–solid fluidized bed with micropore sponge was proposed for fine coal beneficiation.

• The method could provide uniform gas distribution and improve density stability.

• The probable error E for −6 + 3 mm coal was 0.12 g/cm3 indicating satisfied separation efficiency.

Dry coal separation has become essential in China because it does not consume water and it reduces environmental pollution. In this study, a method for improving fluidization quality in a fluidized bed separator using a micropore sponge is proposed. The separator is used for fine coal beneficiation. The pressure drop across the distributor and bed fluidization characteristics were analyzed to evaluate fluidization quality. The beneficiation efficiency for fine coal was further investigated by using a laboratory-scale fluidized bed with and without a micropore sponge. With the sponge, the highest pressure drop fluctuation factor decreased from 0.23 to 0.16, indicating an improvement in density stability. The modified separation method reduced the ash content of a sample of fine coal from 23.83% to 10.70%. The probable error efficiency value E for −6 + 3 mm coal was 0.12 g/cm3, close to the efficiency error values reported for other dry-beneficiation techniques. The separation results show that using a sponge in the fluidized bed can readily improve the efficiency of fine coal beneficiation.