- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

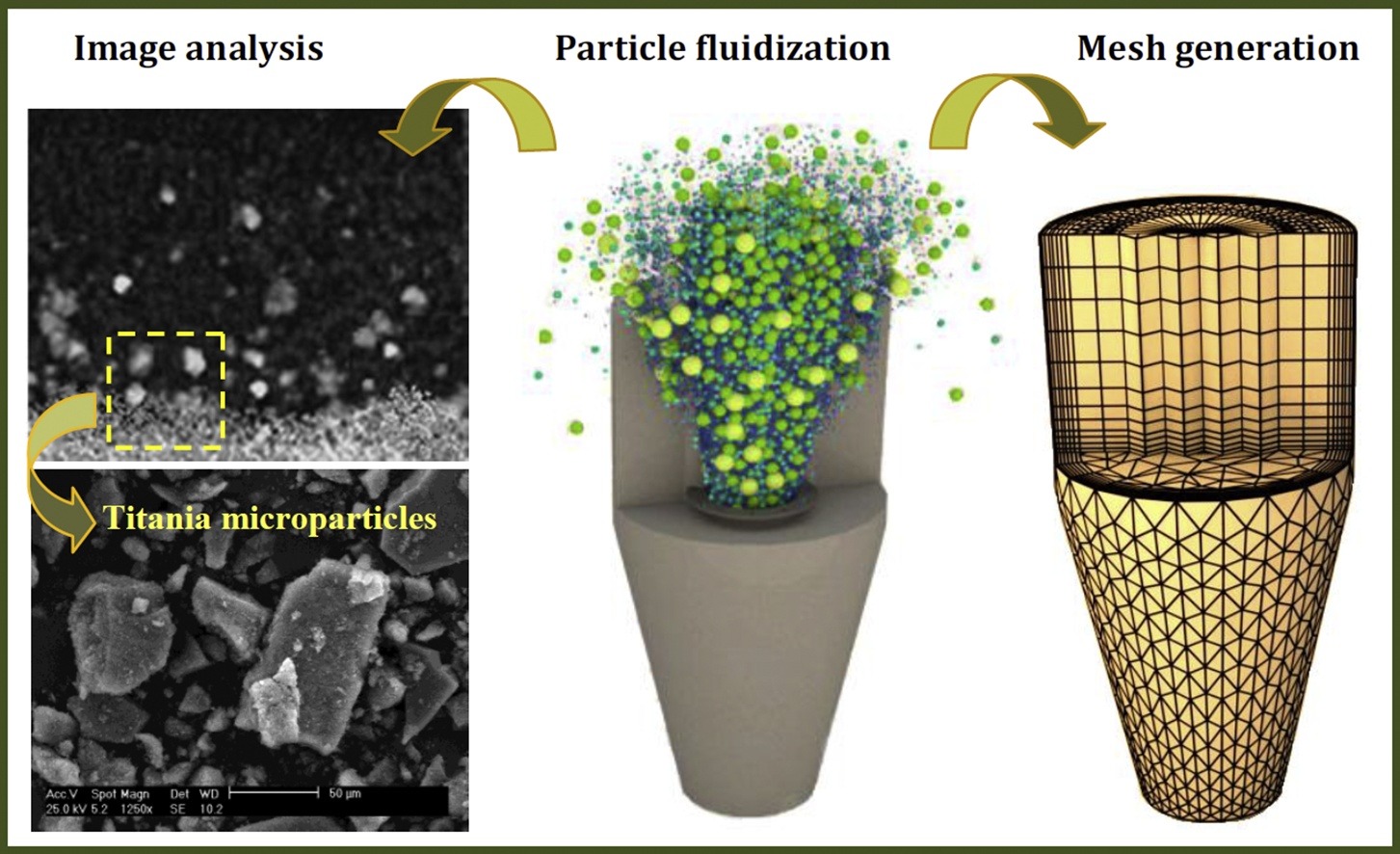

• Pressure gradients and velocity fields of microparticles were studied in a conical vessel.

• Numerical analysis was performed to predict the bed fluidization characteristics.

• A CFD model was presented to study the mesh sensitivity to size and shape.

• Simultaneous effects of mesh configuration and wall boundary conditions were studied.

• Computational grids and the effects of mesh refinement were analyzed.

The reliability and accuracy of numerical results of microparticle fluidization in a conical bed, affected simultaneously by mesh refinement, the grid configuration and the wall boundary condition (BC), are analyzed. Specifically, pressure gradients and velocity profiles of titania powder are studied for a conical bed. The Gidaspow drag correlation and different wall BCs are considered using a Eulerian–Eulerian two-fluid model. Predictions of the pressure fluctuation, power spectra of the corresponding pressure fluctuations, bed pressure drop, minimum fluidization velocity, axial solid velocity, bed expansion ratio, and particle size distribution are compared with experimental data. Mesh sensitivity analysis using hexahedral and tetrahedral cells with a uniform mesh and near-wall mesh refinement is conducted to investigate the effects of mesh configurations in estimating particle flow patterns. Simulations show that significant savings in terms of computational time are realized by choosing a uniform mesh while the hexahedral structure, the near-wall mesh refinement, and the free-slip BC give the closest fit to the experimental data.