- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

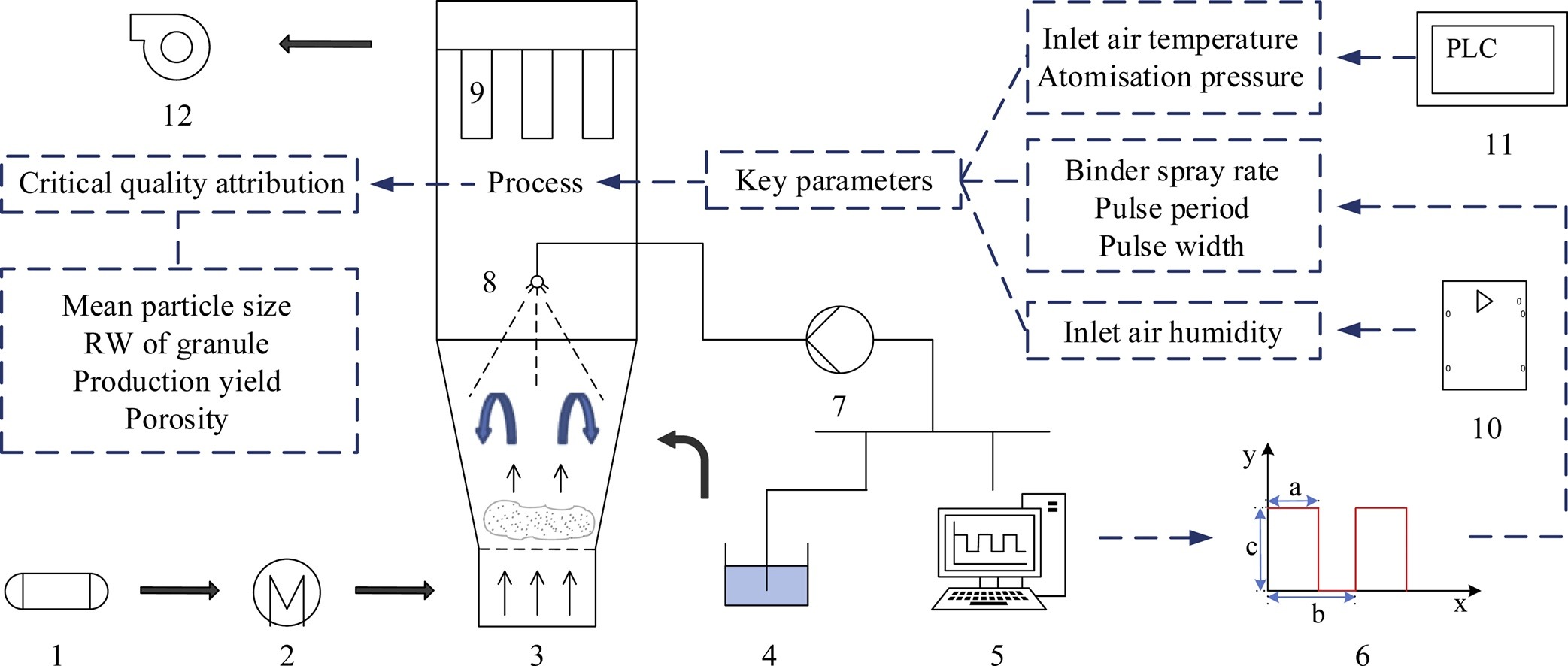

• A novel definitive screening design was used to investigate the granulation process.

• Quantified the relationships between studied factors and critical quality attributes.

• The differing and peculiar roles of six critical process parameters were interpreted.

• A design space for the pulsed spray fluid bed granulation was determined.

The pulsed-spray fluid-bed granulation (PSFBG) process was investigated and optimized using definitive screening design, a recently proposed new class of three-level design of experiment method. Such a design enabled quadratic models to be established that described the effect of six input process parameters – inlet air temperature, inlet air humidity, binder spray rate, atomization pressure, pulse period, and pulse width – on the granule quality in a PSFBG process. Mathematical models of the mean particle size, relative size distribution width, production yield, and porosity were developed to quantify the relationships between the influencing factors and critical quality attributes. On the basis of constraints on the desired granule properties, a design space for PSFBG was determined and ranges of the operating parameters were defined. An acceptable degree of prediction was confirmed by validation experiments, demonstrating the reliability and effectiveness of using definitive screening design to study the PSFBG process. This method can accelerate screening and optimization of this process within a large multidimensional design space.