- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

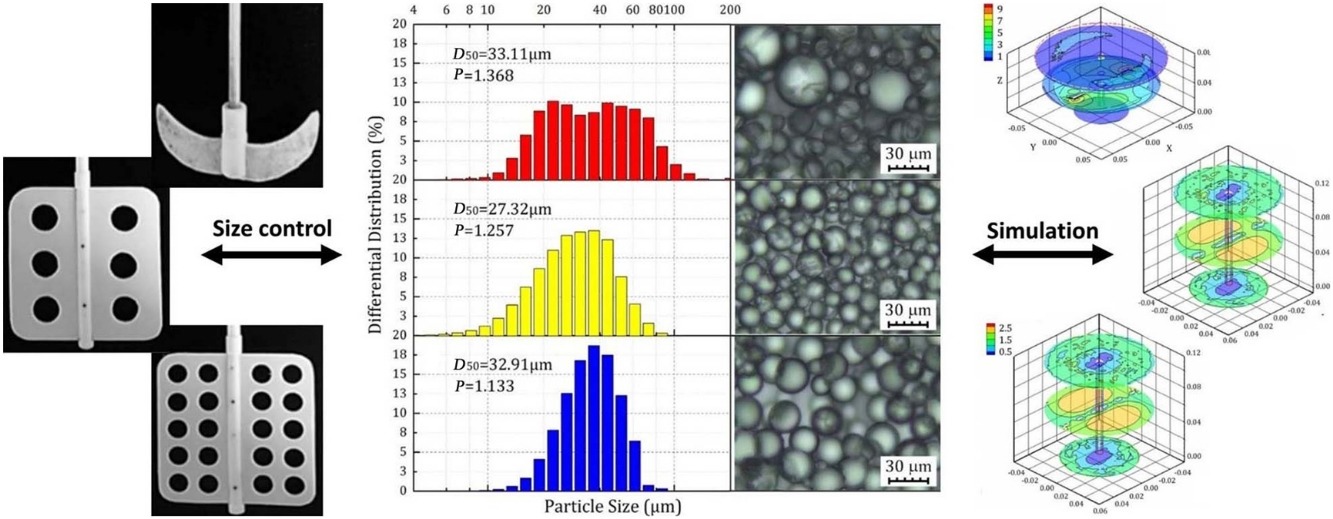

• The control of microcapsule size was realized by a designed agitator paddle system.

• Effects of stirring speed and reactor dimension on prepared microcapsule size were studied.

• Flow field in different agitator paddle systems was investigated by CFD.

• Average fluid velocity was negatively-linearly correlated with average microcapsule size.

Controlling the size of fragrance microcapsules using designed agitator paddles was investigated and studied by CFD simulation. First, different fluid flows were established by varying stirring speeds, reactor scales, and agitator paddle design, and the effects of each on particle size and distribution of prepared microcapsules were determined. The experimental results showed that the pattern design of orifices in the plate paddles control the flow field well. Narrow particle-size distributions of the microcapsules were obtained. The fluid flow characteristics including fluid velocity field, turbulent kinetic energy field, and shear stress distribution for the different agitator paddle types in different reaction kettles were simulated using CFD technology. The correlations between simulated data and experimental results were analyzed. Significantly, the simulated average flow velocity was found to show good negative linear correlation with the average particle size of prepared microcapsules, with a correlation of y = –2.166x + 42.626.