- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

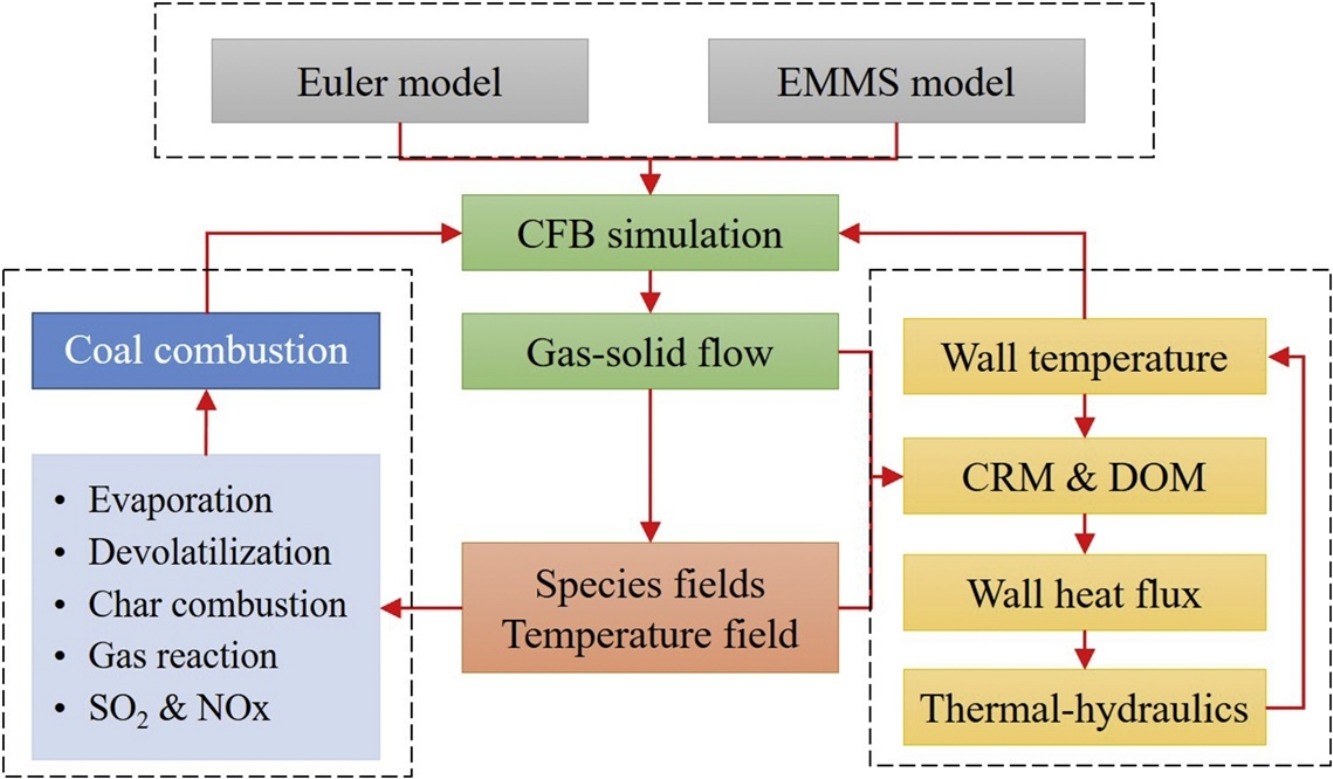

• A 3D numerical combustion model for large-scale supercritical CFB boilers was developed.

• The model consists of gas–solids hydrodynamics, coal combustion, and heat transfer in furnace.

• Thermohydraulics in tubes was considered to couple the heat transfer processes.

A combustion model of a large-scale supercritical circulating fluidized bed (CFB) boiler was developed for comprehensive computational-fluid-dynamics analysis. The model incorporates gas–solid hydrodynamics, coal combustion, heat transfer on heat exchange surfaces in the furnace, and heat transfer between furnace and working medium in the heat transfer tubes. In simulating the dense and dilute phases in the furnace, the gas–solid hydrodynamics is based on the Euler–Euler model and energy-minimization multiscale drag model. Coal combustion entails evaporation, devolatilization, char combustion, gas homogeneous reaction, and pollutant emission. The coefficient of heat transfer between gas–solid and the waterwall is estimated using the cluster renewal model, and for radiation, the discrete ordinate model is used. Moreover, thermohydraulic processes in the membrane wall are also included in the heat transfer process. The model was successfully applied in simulations of a 350-MW supercritical CFB boiler. Detailed distributions of solids concentration, oxygen, heat flux, and working medium temperature in the boiler furnace are presented.