- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

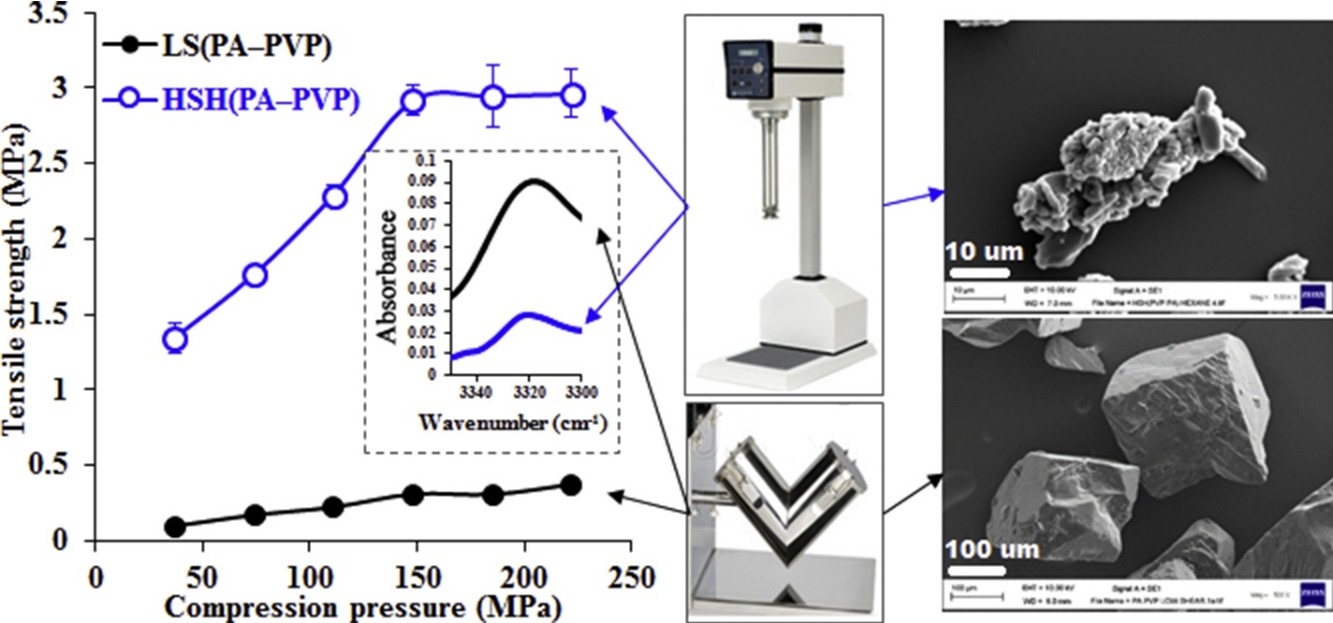

• Mixing conditions had a deep influence on paracetamol–polyvinylpyrrolidone mixture.

• High energy mixing is recommended to achieve excellent tableting properties.

• Powder cohesivity increased with increasing the energy introduced during mixing.

• Hydrogen bonding was detected in the mixtures prepared via high energy mixing.

Monoclinic paracetamol (PA) is notorious as a poorly compactible model drug. Polyvinylpyrrolidone (PVP) is a polymer that can act as an effective binder to improve the mechanical properties of PA. It is surprising however that the role of mixing conditions on the physicochemical and mechanical properties of PA–PVP mixtures has not been reported previously. The results of this work showed that PA–PVP mixtures containing 5% (w/w) PVP prepared using high energy mixing conditions had considerably smaller particle size distributions and higher cohesivities than mixtures prepared using low energy mixing conditions. Solid-state analysis did not detect any change in the monoclinic crystalline form of PA after mixing with PVP. The following rank order of tabletability for PA–PVP mixtures was obtained according to the mixing condition: low shear ∼ medium shear < dry high shear < wet high shear < high-speed homogenization. A higher level of hydrogen bonding was detected in the mixtures prepared via high energy mixing conditions than in those prepared using low energy mixing conditions. Mixing is therefore a critical process that needs to be optimized during the preparation of interactive mixtures for tableting.