- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Suspensions of dextran-covered poly(d,l-lactide) particles were prepared.

• Emulsion/solvent evaporation (diffusion) process was used with dextran derivatives.

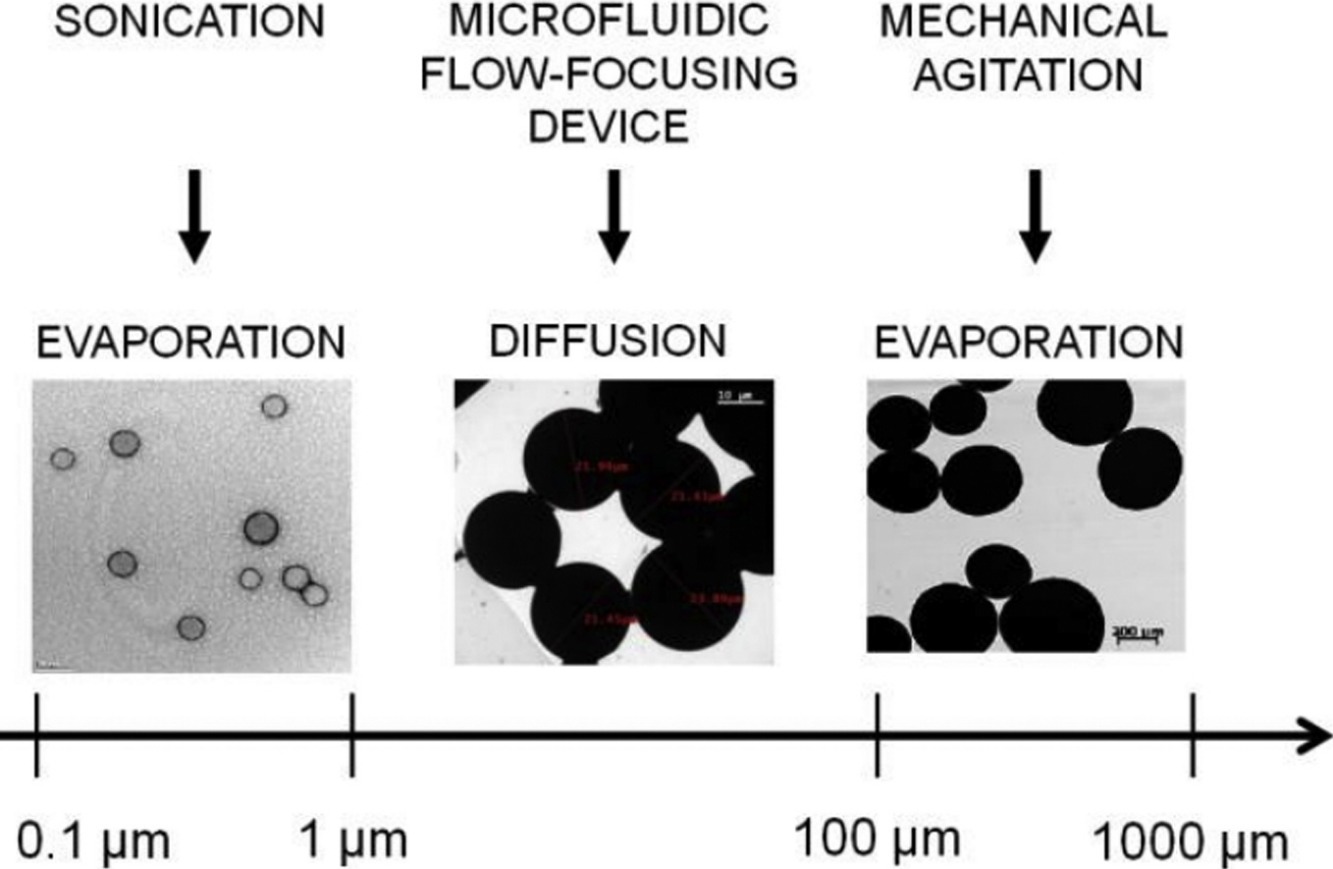

• Varying emulsification conditions led to a wide range of particle diameters.

• Encapsulation of alkyl gallates in each particle type was performed and evaluated.

• Release kinetics were monitored and compared according to the class of particles

Dextran-covered poly(d,l-lactide) (PLA) nano- and microparticles were prepared using an emulsion/solvent evaporation (or diffusion) process for the encapsulation of alkyl gallates (AGs). In the first step, a solution of PLA and AG in ethyl acetate was emulsified to give an aqueous phase containing a hydrophobically modified dextran, which acted as a stabilizer. The second step involved solvent evaporation or diffusion. The emulsification conditions were varied, which allowed for the preparation of nano- and microparticle suspensions covering a wide range of surface-average particle diameters from 0.1 μm (sonication) to 500 μm (stirring with a magnetic bar), with narrow and reproducible size distributions. Continuous microfluidic emulsification in a flow-focusing system led to well-defined microparticles, in the 10–50 μm range. Particles loaded with octyl gallate (OG) and nonyl gallate (NG) were obtained using the three processes, and we showed that the encapsulation efficiency of OG and NG varied significantly depending on the emulsification process. The effect of particle size on the mechanism of in vitro release of encapsulated AGs was investigated. The kinetics of release were controlled either by Fickian diffusion within the solid core or swelling and hydrolytic degradation of the PLA matrix, depending on the pH of the external medium.