- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

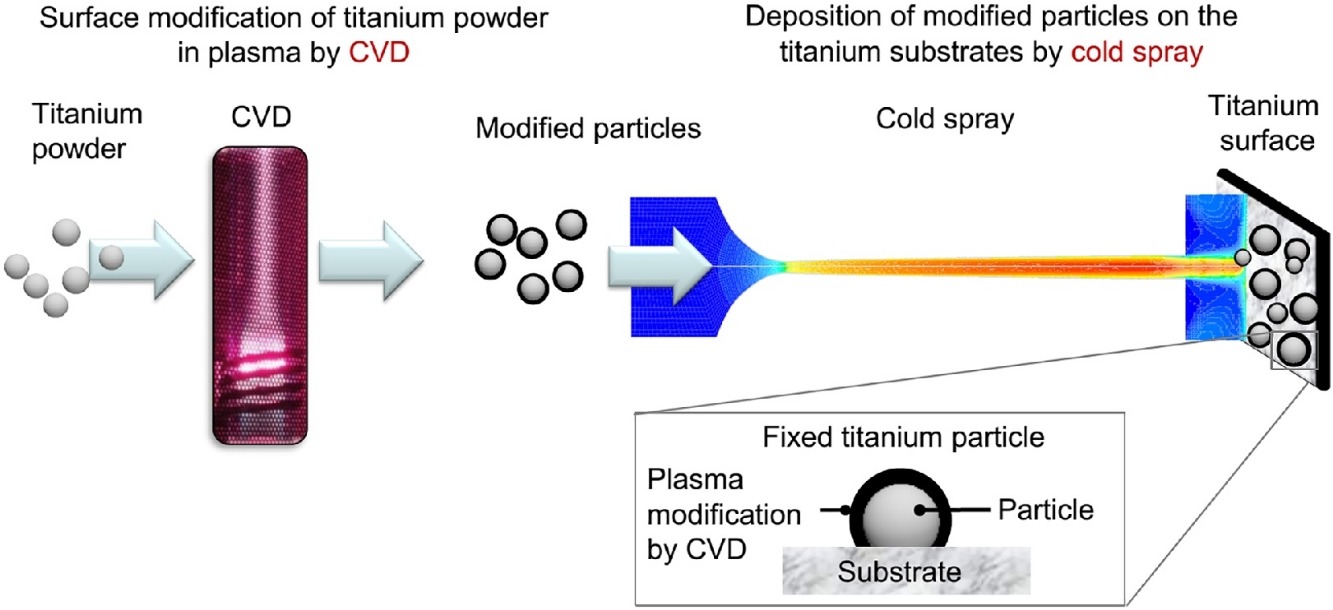

• Ti particles underwent plasma treatment in a PE-CVD process with N2, C2H2 and Ar.

• Treatment increased the deposition efficiency of cold sprayed Ti particles.

• Particle impact velocities and temperatures were obtained by CFD simulations.

• Surface modification shows influence on water contact angle and friction behavior.

Although the deposition mechanisms of the cold spray process are well studied, few reports regarding the use of surface-modified particles exist. Herein, titanium particles 3–39 μm in size and with an angular shape were modified in a plasma-enhanced chemical vapor deposition process in Ar, Ar-C2H2, and N2 plasmas. After Ar-C2H2 and N2 treatments, the respective presence of TiC and TiN on the particle surface was confirmed via transmission electron microscopy and energy-dispersive X-ray, X-ray photoelectron, and Raman spectroscopies. The powders were deposited on titanium substrates by cold spray experiments, where unmodified particles up to 10 μm in size exhibited a successful surface bonding. This finding was described by an existing analytical model, whose parameters were achieved by computational fluid dynamics simulations taking the particle shape factor into account. A good deposition of plasma-modified particles up to 30 μm in size was experimentally observed, exhibiting an upper size limit larger than that predicted by the model. Higher surface roughness values were found for plasma-modified particles, as determined by 3D scanning electron microscopy. The water contact angle indicated that argon treatment influenced the wettability. Tribological tests showed a decrease of the initial friction coefficient from 0.53 to 0.47 by microstructuring.