- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

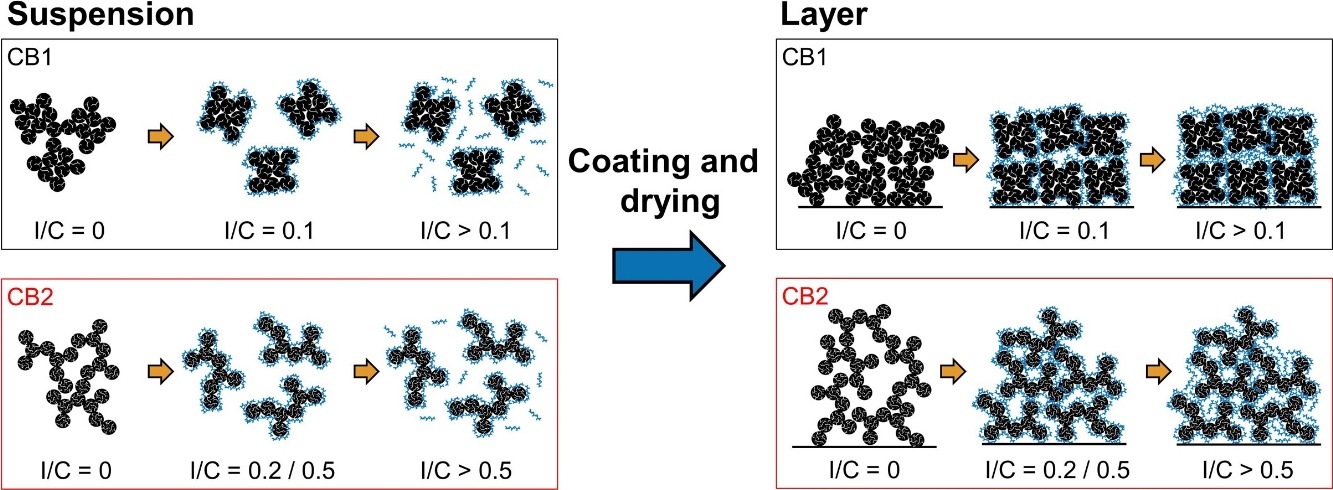

• Higher suspension viscosities were observed for higher-branched carbon blacks.

• Larger porosity and less cracking for layers with higher-branched carbon blacks.

• Addition of ionomer improves the colloidal stability of carbon black particles.

• Addition of ionomer reduces film cracking and leads to thinner layers.

The performance of proton exchange membrane fuel cells (PEMFC) is strongly determined by the structure and composition of the electrode layer. The interactions between the ionomer, carbon black particles, and solvent affect the suspension properties and thus the layer morphology. We analyze the effect of the ionomer-to-carbon (I/C) weight ratio for two different types of carbon black on the suspension and layer characteristics. Highly branched carbon blacks with a high surface area tend to form less cracked layers. As less branched carbons can pack together more closely, a smaller pore size results in a larger capillary pressure during drying and thus more cracks. The added ionomer adsorbs on the carbon particles and improves the colloidal stability of the carbon black particles. The carbon black aggregates are thus smaller, resulting in closer packing and thinner layers. Moreover, the addition of the ionomer increases the critical coating thickness (CCT) of the layers because drying stresses are dissipated by the deformation of the ionomer, preventing crack formation. An optimum I/C weight ratio is identified for optimal layer formation and minimized crack formation.