- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

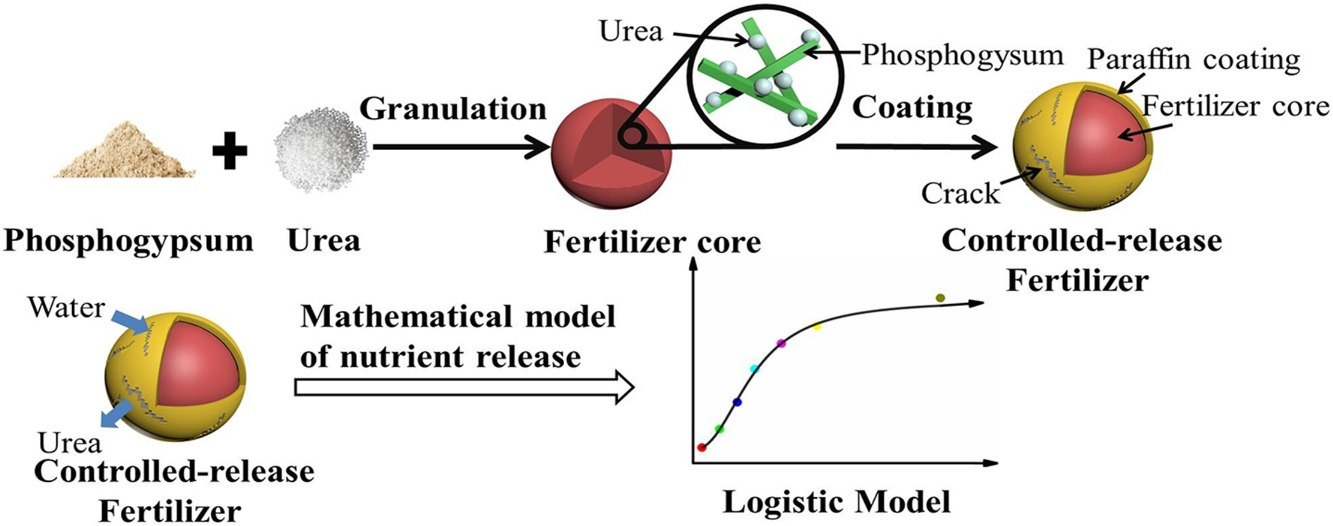

• Phosphogypsum granulation was first used to produce slow-release urea particles.

• Expansion of brittle cracks in the coating resulted in faster urea dissolution.

• Span™ 80 improved adhesion between the paraffin coating and fertilizer core.

We developed a novel slow-release nitrogen fertilizer with the aim of increasing the efficiency of urea use, recycling phosphogypsum, and reducing related pollution. Phosphogypsum was used as a granulating agent and carrier for urea to prepare a novel fertilizer core, which was coated with paraffin wax. Span™ 80 was added to the paraffin to improve the wetting and adhesion between the paraffin coating and the fertilizer core. Paraffin-coated urea particles were prepared as a control sample using this method and their urea-release behavior was investigated. The results showed that less than 35% of urea from the paraffin-coated phosphogypsum-granulated urea was released over 28 days of submersion in water. The urea release was sustained much longer than that of paraffin-coated urea (only 7 days due to the expansion of brittle cracks in the coating). The release patterns of all coated fertilizers followed a logistic model. The release efficiency of paraffin-coated fertilizers could be improved by increasing the particle size of the fertilizer cores and improving adhesion between the paraffin coating and fertilizer core.