- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

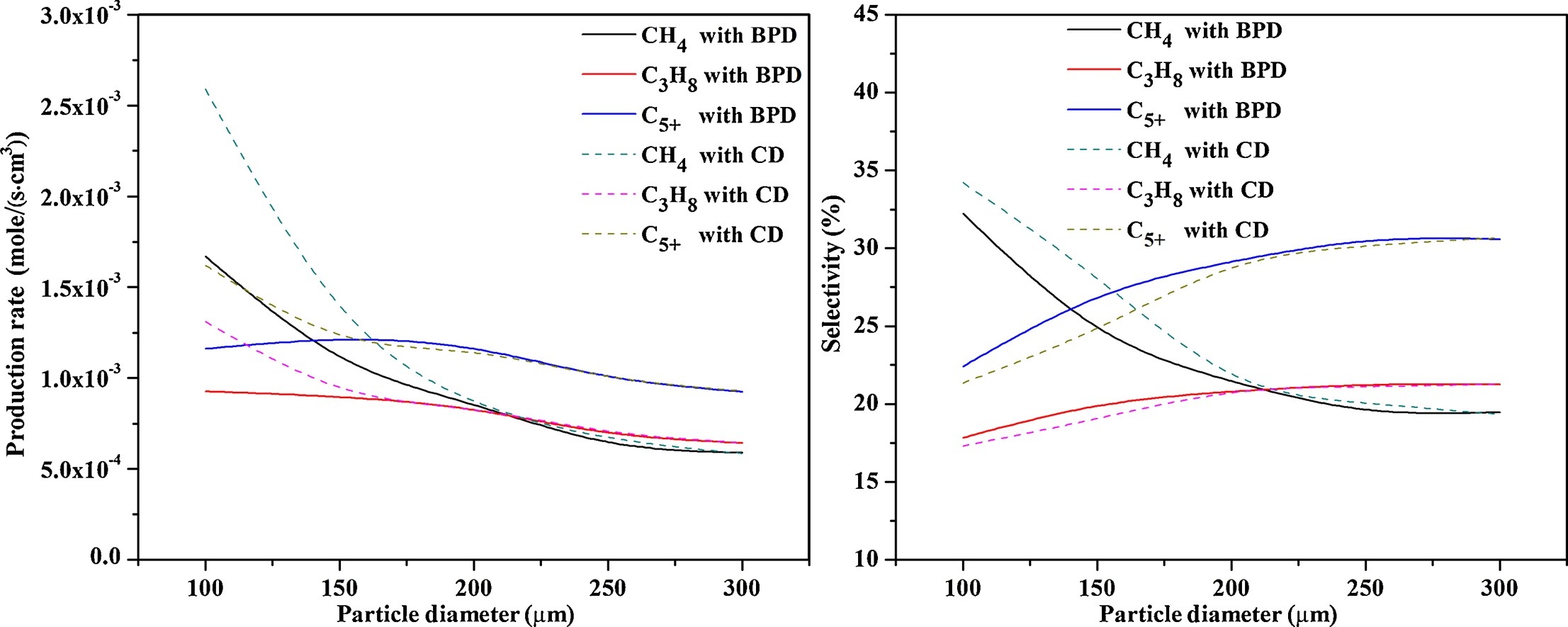

• Fluidized-bed reactor CFD model was coupled with Fischer–Tropsch synthesis reaction.

• Fischer–Tropsch species included CO, H2, H2O, CH4, C3H8, C10H22, and C22H46.

• Branched pipe and circular gas distributors were designed.

• Circular distributor gave better gas–solid contact than branched pipe distributor.

• This led to higher reaction rates and higher solid-phase temperature distribution.

Circular and branched pipe distributors were designed for Fischer–Tropsch synthesis in a fluidized-bed reactor. A numerical investigation of the effects of these distributors on product selectivity and production rate was performed. Under the same conditions, the circular distributor gave higher production rates for small diameter particles. For superficial gas velocities ranging from 5 to 15 times the minimum fluidization velocity, the production rates of methane and C5+ (the sum of C10H22 and C22H46) were 18%, which was 2% higher than those using the branched pipe distributor, while the C5+ selectivity was 1% lower. For deeper beds, the circular distributor led to higher production rates and the selectivity for C5+ was 5% lower than that using the branched pipe distributor.