- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Powder discoloration arises from dry neutralization of linear alkylbenzene sulfonic acid.

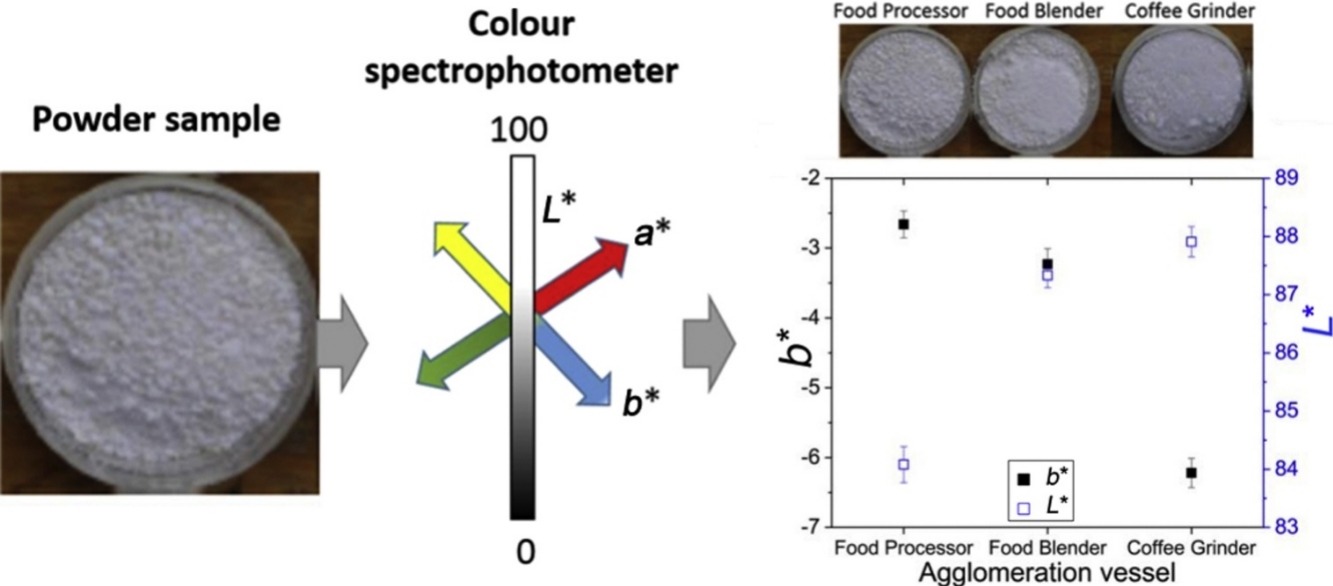

• Particle size greatly affects L*a*b* color values.

• Optimization of raw material purity and granule temperature minimizes product discoloration.

• Spray application of an optical brightener dispersion improves color performance.

• Further optical brightener application improves powder whiteness.

The appearance of detergent powder plays an important role in consumer perception of powder effectiveness for cleaning applications. In this study, we investigated the influence of numerous formulation and processing conditions on product discoloration. Product color was scrutinized using the L*a*b* color space, and in particular, L* and b*. Particle size, the method for introducing the optical brightener, and the raw material grade were very important in controlling the optical properties of detergent granules. As the particle size decreased, the light reflected to the observer appeared brighter and bluer. This was observed as increased whiteness from L* = 84.03 with a particle size of >841 μm to L* = 90.59 with a particle size of <250 μm. Reducing the level of impurities found in the raw materials by changing the material source also improved color definition. A key finding is that the optical brightener should be applied by spraying and prepared by dispersion rather than dissolution. This improves the distribution within the granules and increases the whiteness when compared with pouring the brightener into the agglomeration vessel. Additional spray applications highlighted that brightener on the granule surface influenced whiteness more than embedded brightener. In addition, we report on the effects of the drying temperature and mixer impeller speed on powder color.