- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

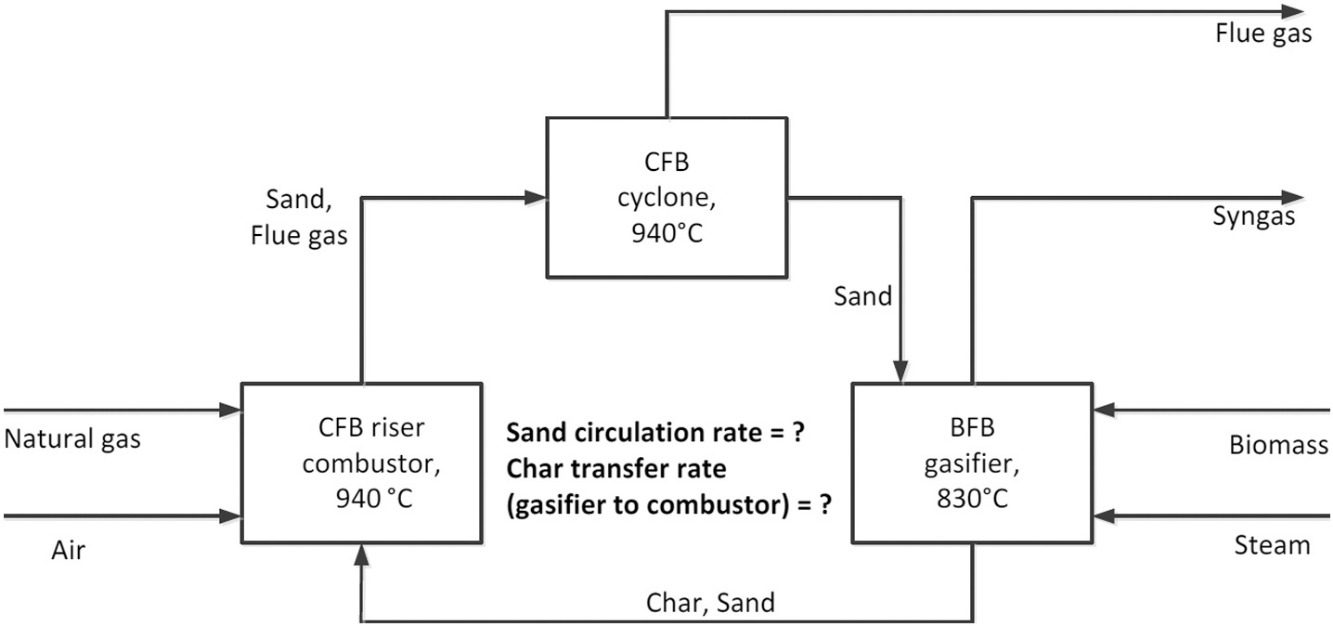

• A novel mass and energy balance method was developed to estimate solids flow rate.

• This method also provides the char transfer rate from the gasifier to the combustor.

• Gasifier heat loss obtained from two independent techniques matched well.

• Estimated solids flow rates compared well with rates measured by another technique.

• No other technique can determine char transfer rate from a gasifier to a combustor.

Operation of a dual fluidized bed, consisting of a riser as combustor and bubbling bed as gasifier, for synthesis gas production from a solid fuel requires determination of the solids circulation rate and char transfer rate. The performance relies on supplying sufficient heat from the combustor to the gasifier by circulation of solids between these two reactors. The flow rate of char is required to track the heat generated in the combustor, which supports endothermic reactions in the gasifier. Direct measurement of these two critical parameters is difficult, with the number of reported techniques capable of working at high temperatures extremely small. An indirect method was developed, using mass and energy balances over the entire system and individual reactors, to estimate the solids circulation rate and char transfer rate. There was general agreement between heat losses estimated from energy-balance calculations and from direct measurement of the outer reactor surface temperature. Under typical gasification conditions, the solids circulation fluxes were estimated to be 45.2 and 55.6 kg/(m2 s) in two independent tests, which were in good agreement with values obtained using a thermal tracer; char transfer rates were calculated to be 1.2 and 0.6 kg/h, which were in reasonable agreement with average biomass feed rates. This method can be applied to dual gasification systems at any temperature or flow rate.