- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Limestone-conveying pipeline of 200 MW circulating fluidized bed boiler was studied.

• Gas–solid flow characteristics of multiple-branching pipeline were simulated.

• Computational particle fluid dynamics methods were employed.

• Effects of air velocity and particle mass flow rate on maldistribution were studied.

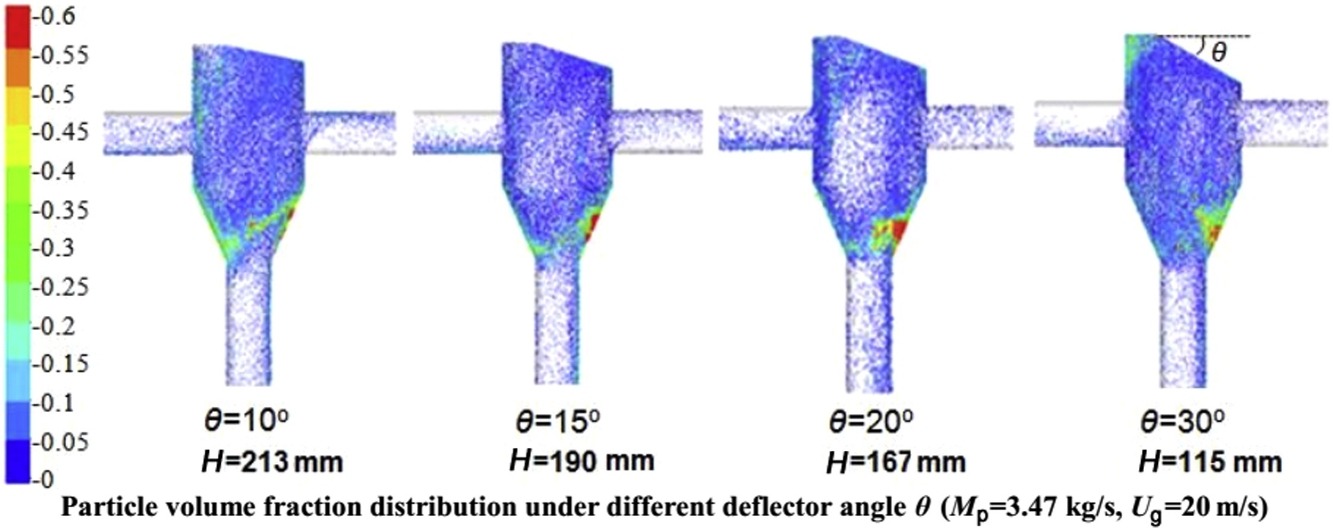

• Adding a deflector at appropriate angle and adjusting height of pipeline distributer mitigated maldistribution.

As one of the most important auxiliary systems of a circulating fluidized bed boiler, the limestone pneumatic conveying system is of great significance to its operation. Maldistribution of powder in the different injecting ports seriously limits inner-furnace desulfurization performance owing to inefficient mixing of limestone powder and SO2. The gas–solid flow characteristics of an industrial-scale multiple-branching limestone-conveying pipeline system of a 200 MW circulating fluidized bed boiler were studied using a computational particle fluid dynamics method. The maldistribution intensity was studied under different operating conditions of air velocity and particle mass flow rate. Simulation results indicated that when the air velocity increased, the maldistribution was mitigated, but when the particle mass flow rate increased, the maldistribution strengthened. To solve this problem, two improved schemes were proposed: adding a deflector at different angles and changing the height of pipeline distributor. According to the simulation, the maldistribution could be efficiently mitigated using a distributor height in the range of 100–120 mm and a deflector angle of 10°–30°.