- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

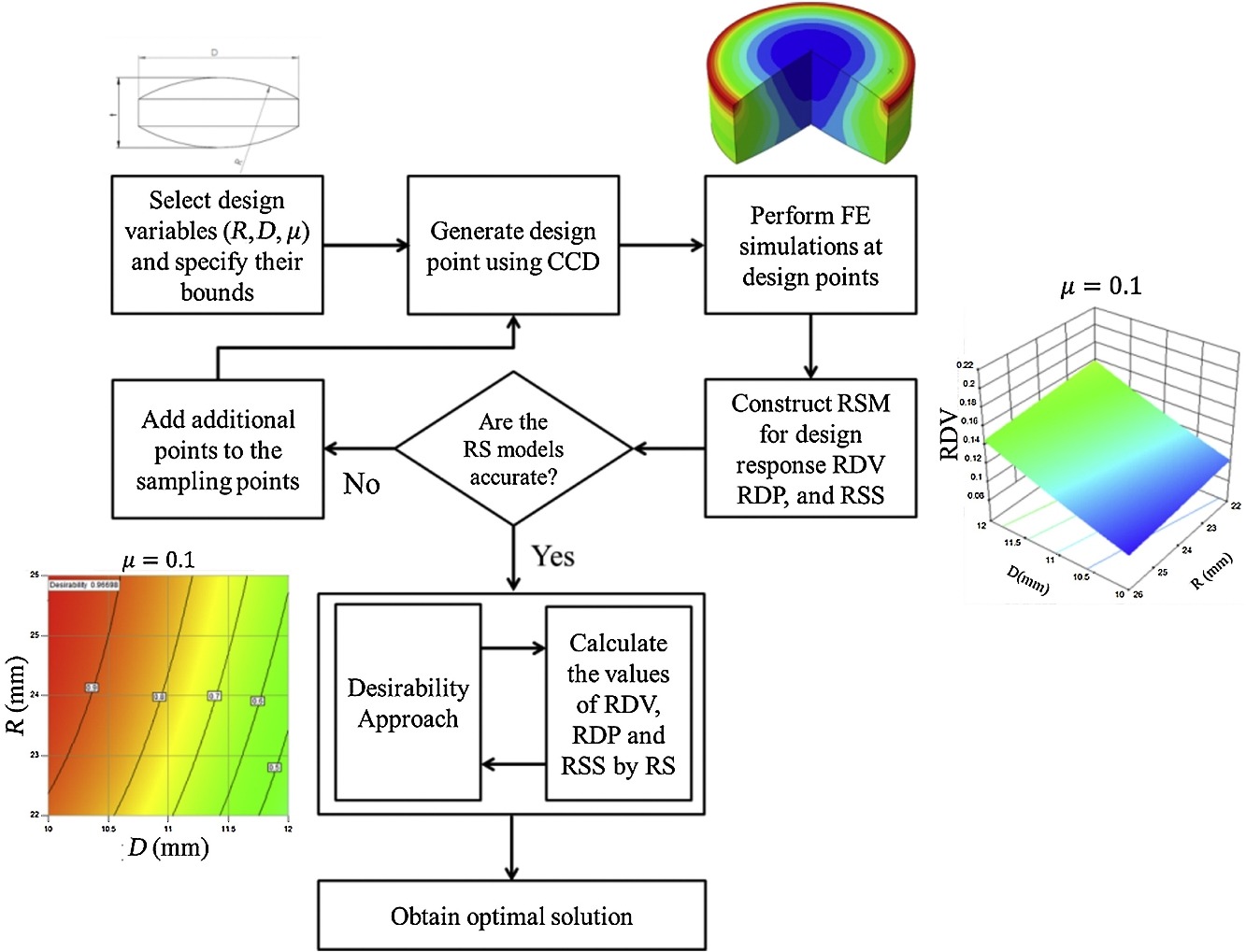

• Convex-faced pharmaceutical tablets were theoretically analysed and optimised.

• Mathematical models of tabletting were designed using response surface methodology.

• The effects of geometrical parameters on compaction responses were evaluated.

• The optimal shape of the convex-faced tablets was determined.

Capping failure, edge chipping, and non-uniform mechanical properties of convex-faced pharmaceutical tablets are common problems in the pharma industry. In this paper, the finite element method (FEM) and design of experiment techniques are used to determine the optimal shape of convex-faced (CF) pharmaceutical tablet which has more uniform mechanical properties and less capping and chipping tendency. The effects of different geometrical parameters and friction on the compaction responses of convex-faced pharmaceutical tablets were first identified and analysed. An FEM model of the tabletting process was generated using the implicit code ABAQUS and validated against experimental measurements. Response surface methodology was used to establish the relationship between the design variables, represented by the geometrical parameters and friction coefficient, and compaction responses of interest including residual die pressure, relative density variation within a tablet, and relative shear stress at the edge of a tablet. A statistical-based optimisation approach was then used to optimise the shape of CF tablets. The obtained results demonstrated how the geometrical parameters and friction coefficient of CF pharmaceutical tablets strongly affect their compaction behaviour and quality.