- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

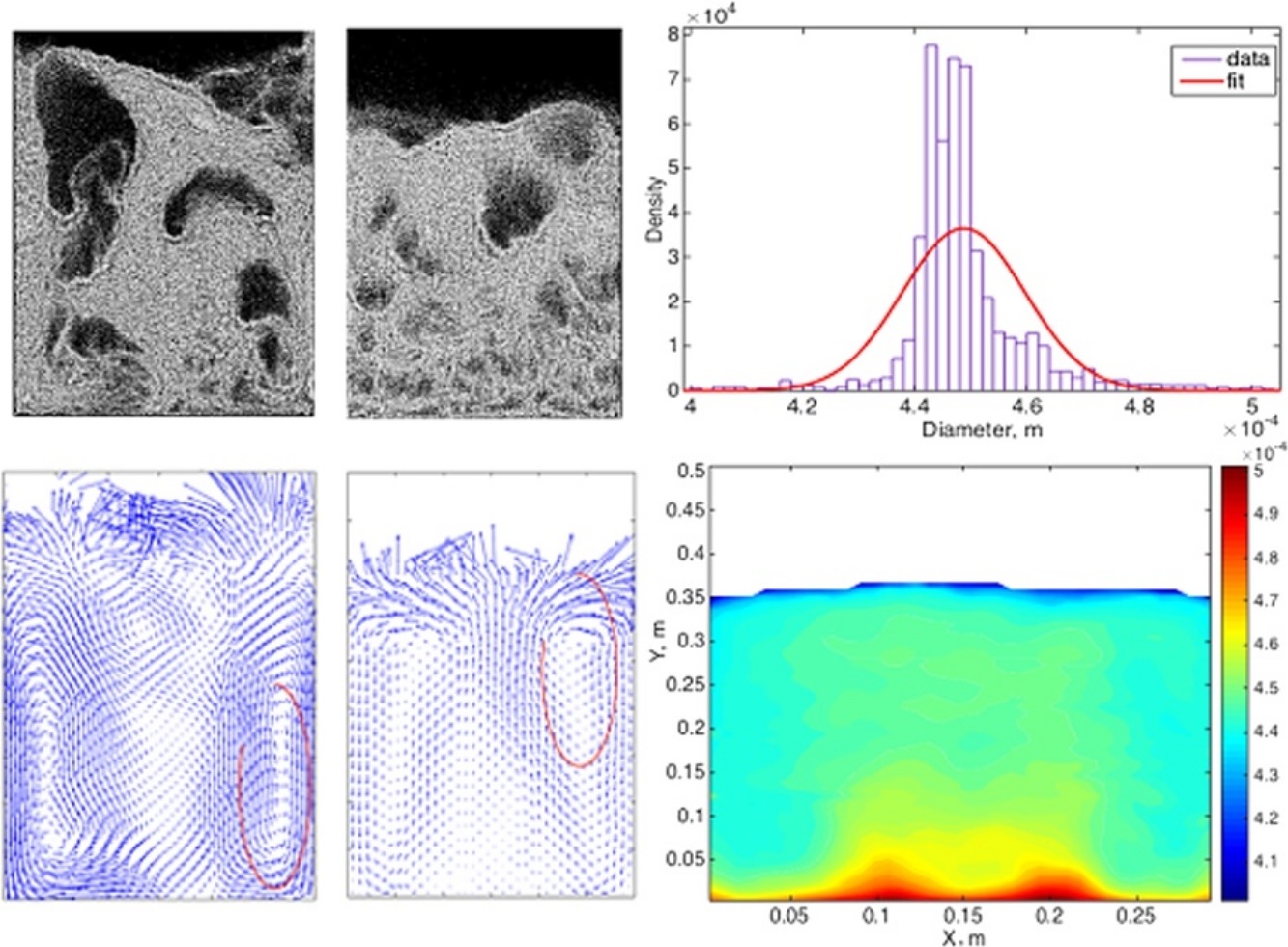

• One mesh cell in thin bed thickness in a DDPM model cannot simulate wall friction.

• Increasing wall friction shifts the circulation center toward the top of the bed.

• Changing specularity factor affects both particle velocity and flow pattern in bed.

• Mixtures with standard deviation to mean diameter of 10% showed segregation.

• Flat size distribution caused non-uniformity even for narrow diameter ranges.

A dense discrete phase model combined with the kinetic theory of granular flows was used to study the bubbling characteristics and segregation of poly-dispersed particle mixtures in a thin fluidized bed. Our simulations showed that in using the hybrid Eulerian–Lagrangian method, the common use of one computational cell in the thickness direction of the thin bed does not predict wall friction correctly. Instead, a three-cell discretization of the thickness direction does predict the wall friction well but six cells were needed to prevent overprediction of the bed expansion. The change in specularity factor (SF) of the model not only affected the predictions of the velocity of particles, but also had a considerable impact on their flow pattern. A decrease in SF, which decreases wall friction, showed an over-prediction in the size of bubbles, particle velocities, and void fraction of the bed, and led to a shift in the circulation center toward the bottom of the bed. The segregation of the Geldart B particles was studied in the narrow range from 400 to 600 μm with a standard deviation less than 10% of the average diameter. Simulations showed that large particles accumulated close to the distributor at the bottom of the bed and the center of the bed, but small particles moved towards the wall and top surface. The decrease in the mean particle size and spread in shape of the distribution improves mixing by up to 30% at a superficial gas velocity of around 2.5 times the minimum fluidization velocity. Log-normal mixtures with a small proportion of large particles had the most uniform distribution with a thin layer of jetsam forming at the bottom of the bed. Finally, experimental verification of the segregation and mixing of polydisperse particles with narrow size distribution is suggested.