- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

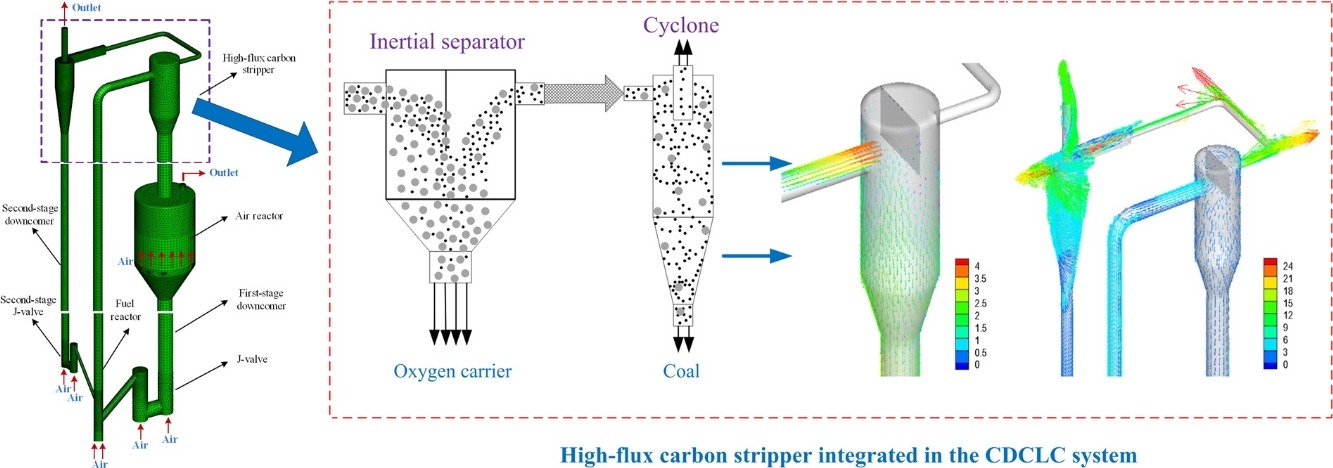

• 3D Eulerian–Eulerian full-loop model for simulating circulation and separation was developed.

• High-flux directional separation mechanisms of binary particle mixtures during CDCLC were studied.

• Effects of operating variables on separation performance of the high-flux carbon stripper were investigated.

Coal-direct chemical-looping combustion (CDCLC) is a promising coal combustion technique that provides CO2 capture with a low energy penalty. In this study, we developed a three-dimensional Eulerian–Eulerian multiphase full-loop model for simulating the circulation and separation of binary particle mixtures in a novel high-flux CDCLC system. This model comprised a high-flux circulating fluidized bed as the fuel reactor (FR), a counter-flow moving bed as the air reactor (AR), a high-flux carbon stripper, two downcomers, and two J-valves. This model predicted the main features of complex gas–solid flow behaviors in the system. The simulation results showed that quasi-stable solid circulation in the whole system could be achieved, and the FR, AR, and J-valves operated in a dense suspension upflow regime, a near-plug-flow regime, and a bubbling fluidization regime, respectively. The multiphase flow model of binary particle mixtures was used to predict the mechanisms of directional separation of binary particle mixtures of an oxygen carrier (OC) and coal throughout the system. A decrease in the baffle aspect ratio of the inertial separator improved the coal selective separation efficiency but resulted in a slight decline in the OC selective separation; this is believed to be the result of weakening of particle collisions with the baffle. A higher FR gas velocity had a slightly negative effect on the OC selective separation efficiency, but improved the coal selective separation efficiency; this can be attributed to an increase in the particle-carrying capacity of the gas stream. A decrease in the coal particle size led to better entrainment of the coal particles by the gas stream and this increased the coal selective separation efficiency. In real CDCLC applications, the operating variables for separation of binary particle mixtures should be comprehensively assessed to determine their positive and negative effects on the carbon capture efficiency, OC regeneration efficiency, gas leakage restraint, energy consumption, and fuel conversion.