- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

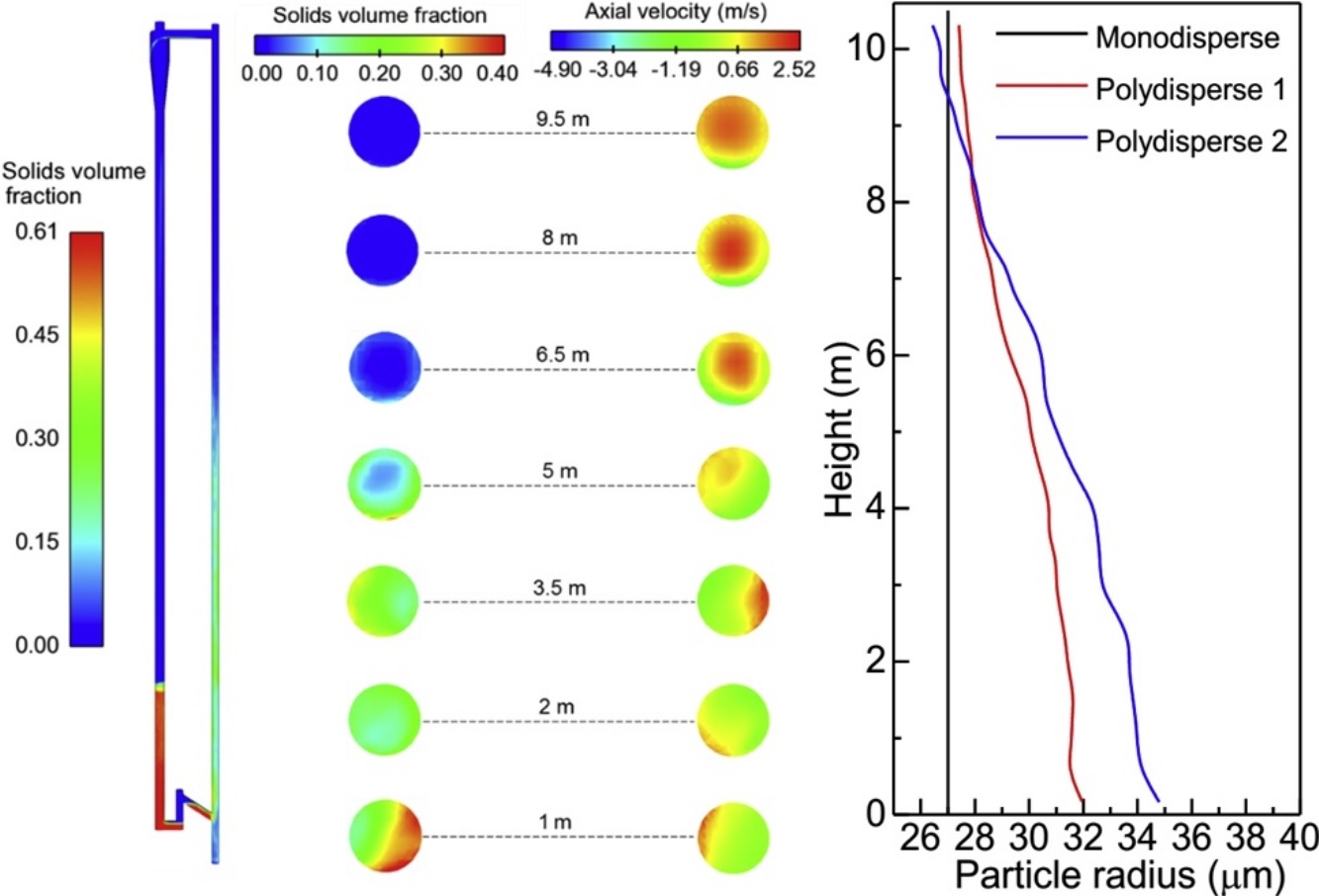

• CPFD model was applied to simulate 3D full-loop CFB.

• EMMS/matrix drag model was compared with the Gidaspow drag model.

• Numerical model was validated by comparison with experimental data.

• Influence of particle-size distribution on hydrodynamics of 3D full-loop CFB was investigated.

A computational particle fluid-dynamics model coupled with an energy-minimization multi-scale (EMMS) drag model was applied to investigate the influence of particle-size distribution on the hydrodynamics of a three-dimensional full-loop circulating fluidized bed. Different particle systems, including one monodisperse and two polydisperse cases, were investigated. The numerical model was validated by comparing its results with the experimental axial voidage distribution and solid mass flux. The EMMS drag model had a high accuracy in the computational particle fluid-dynamics simulation of the three-dimensional full-loop circulating fluidized bed. The total number of parcels in the system (Np) influenced the axial voidage distribution in the riser, especially at the lower part of the riser. Additional numerical simulation results showed that axial segregation by size was predicted in the two polydisperse cases and the segregation size increased with an increase in the number of size classes. The axial voidage distribution at the lower portion of the riser was significantly influenced by particle-size distribution. However, radial segregation could only be correctly predicted in the upper region of the riser in the polydisperse case of three solid species.