- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

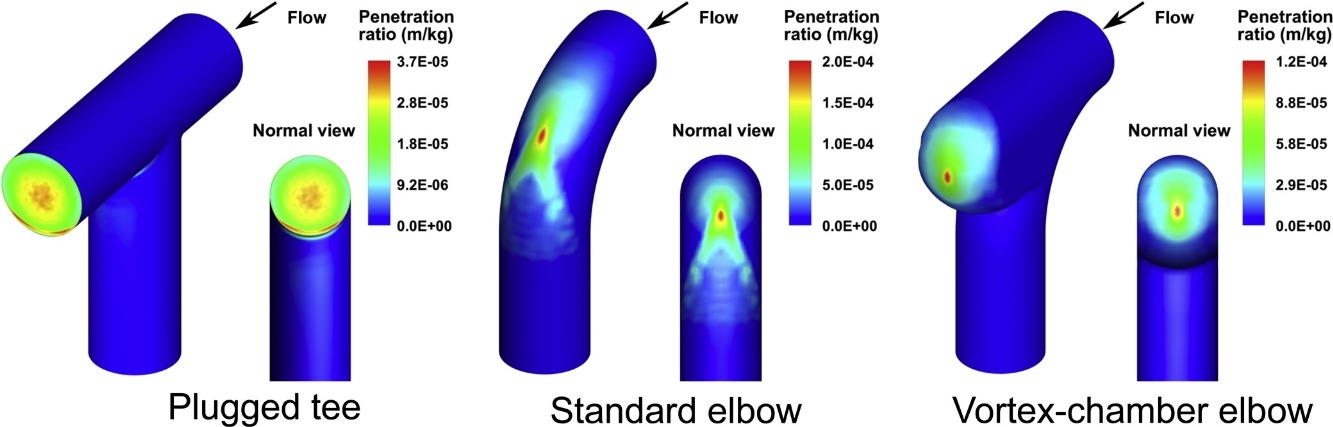

• The relative erosion between two pipe fittings and a standard elbow is assessed.

• The plugged tee and vortex-chamber provide similar mechanisms for reducing erosion.

• The vortex-chamber elbow is the best option when dealing with higher mass loadings.

• For diluted flows, the plugged tee has mechanisms that favor an erosion reduction.

Elbows in pneumatic conveying systems are normally prone to the erosive effects of conveyed particles. There are a number of solutions available to reduce such damage. A widely used geometric alternative for replacing the 90° elbow and reducing erosive wear is the plugged tee. Another option, although less commonly used, is the vortex-chamber elbow. In both cases, the effective reduction in erosion brought about is unclear, as it strongly depends on the operating conditions. The present study assesses relative erosion among the plugged tee, vortex-chamber elbow, and standard elbow for a dilute gas–solid multiphase flow. A numerical model is employed to predict the penetration ratio and validated using experimental data for the plugged tee. Simulations are run for the standard and vortex-chamber elbows and plugged tee under the same conditions to compare the mechanics involved and the relative erosion reduction. The analysis uses variables relating to particle–wall interactions (impact angle, impact velocity, impact frequency) to illustrate the nature of the erosive process in each pipe fitting. In general, the geometric configurations of both the plugged tee and vortex-chamber elbow promote changes in particle dynamics that reduce the rate of erosion. On the basis of the relative erosion of the standard elbow, the plugged tee proves to be an interesting option in cases of a low mass loading, while the vortex-chamber elbow demonstrates its erosion reduction potential for higher mass loading conditions. Furthermore, the advantages and disadvantages of each fitting are highlighted.