- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

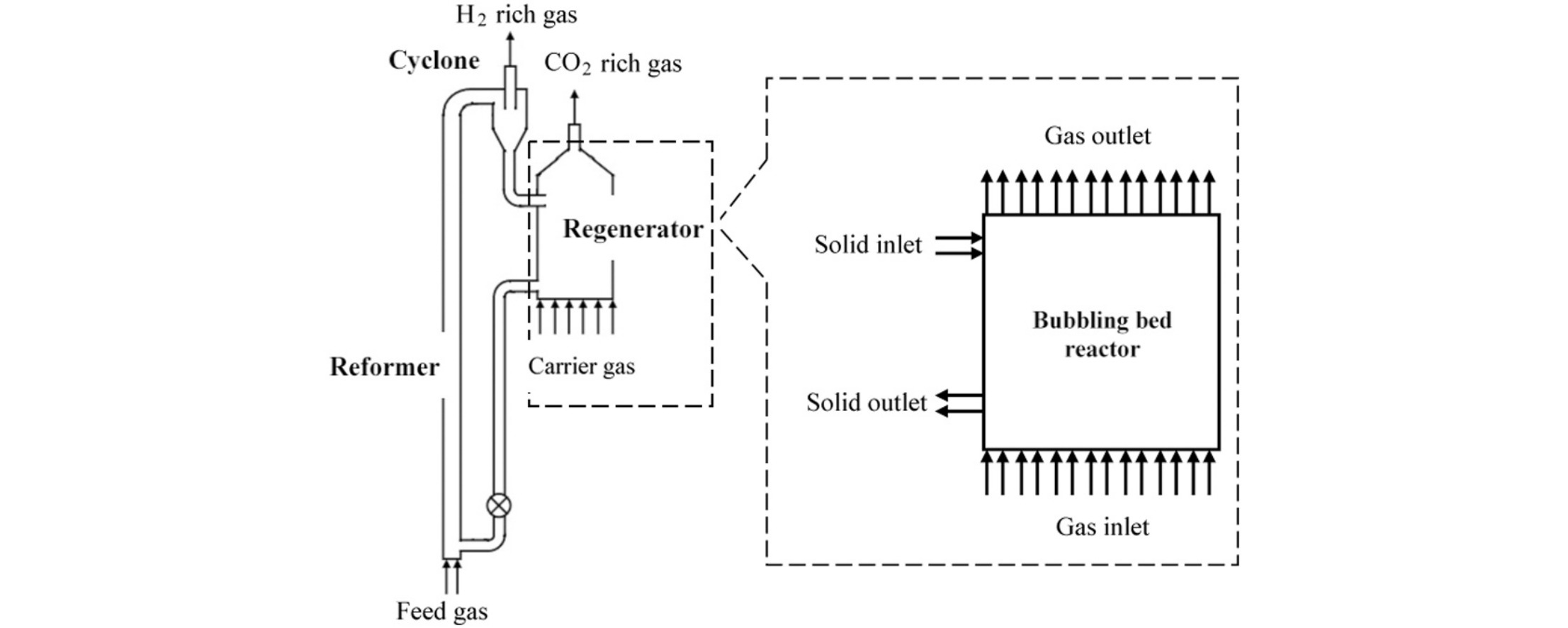

• Dolomite was the selected sorbent for sorption enhanced steam reforming.

• Dolomite decarbonation kinetics was investigated via multiphase fluid dynamic models.

• The sorbent regenerator was preliminary designed in a 2D system.

• Used dolomite could be completely regenerated through double stage regenerators.

In this work, the sorption enhanced steam reforming (SESR) method was developed for improved hydrogen (H2) production, and the drawbacks of conventional steam reforming processes on H2 yield and purity were overcome. However, the SESR process is discontinuous and requires regeneration after sorbent saturation with CO2. The circulating fluidized bed reactor (CFBR) system has previously been proposed for continuous H2 production, with both reforming and sorbent regeneration occurring simultaneously. The main aim of this work was to determine the feasibility and performance of SESR with a proper design and conditions in conjunction with the CFBR system. The reforming riser and bubbling bed regenerator are studied separately but related to each other. Two-dimensional transient models using the Euler‒Euler approach and kinetic theory of granular flow were used for fluid dynamic simulations combined with the decarbonation kinetics of dolomite, to investigate a conceptual regenerator system and determine its key conditions. A mixture of the Ni-based catalyst and dolomite from the risers was injected with a flux of 200 kg/(m2 s) and a catalyst to sorbent ratio of 2.54 kg/kg. A double-stage bubbling bed regenerator system was designed with 1.2 m width, 0.8 m bed height, a gas inlet velocity of 0.2 m/s and solid preheating at 950 °C. The used dolomite was regenerated with an assumed CaO conversion of 3%; the almost fresh dolomite was then released with good mixing of the catalyst and sorbent.