- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A light alkanes dehydrogenation circulating fluidized bed reactor was assessed.

• The designs of key equipment in the reactor and regenerator were studied.

• Attrition properties of different types of catalysts used in the unit were examined.

• Recommendations and improvement opportunities were proposed and accepted.

• Insights were obtained into the improvement of fluidization behavior.

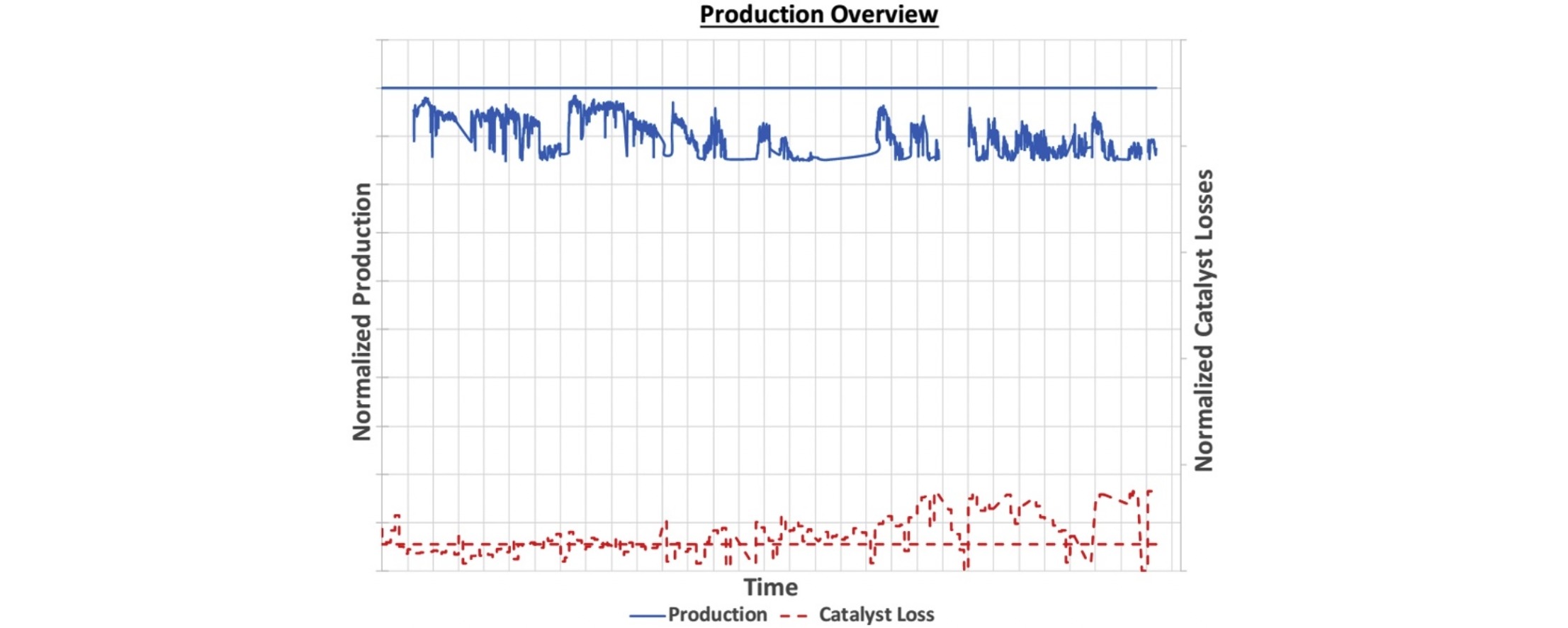

The dehydrogenation of light alkanes to corresponding light olefins is an important industrial process. The present work involved the assessment of a commercial alkane dehydrogenation circulating fluidized bed (CFB) reactor unit that had been underperforming and exhibiting higher than expected catalyst losses over a long period of time. Several aspects of this unit related to fluidization, catalysis, and process engineering were investigated to understand and resolve these issues. The primary focus was on the fluidization aspects of the process, along with a comparison of equipment design and operating conditions to accepted best practices in the industry. The designs of key equipment in the reactor and regenerator, including feed distributors, fuel gas distributors, cyclones, baffles, strippers, transfer lines, risers, riser terminations, and refractories, were studied in detail. The attrition rates of different types of catalysts used in the unit were also examined. Several recommendations and improvement opportunities were proposed to significantly increase light olefins production and reduce catalyst losses, and were accepted and implemented. This study provides insights into means of improving fluidization behavior and highlights the viability of employing a systematic approach to determine the underlying root causes of issues in a commercial CFB reactor unit.