- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

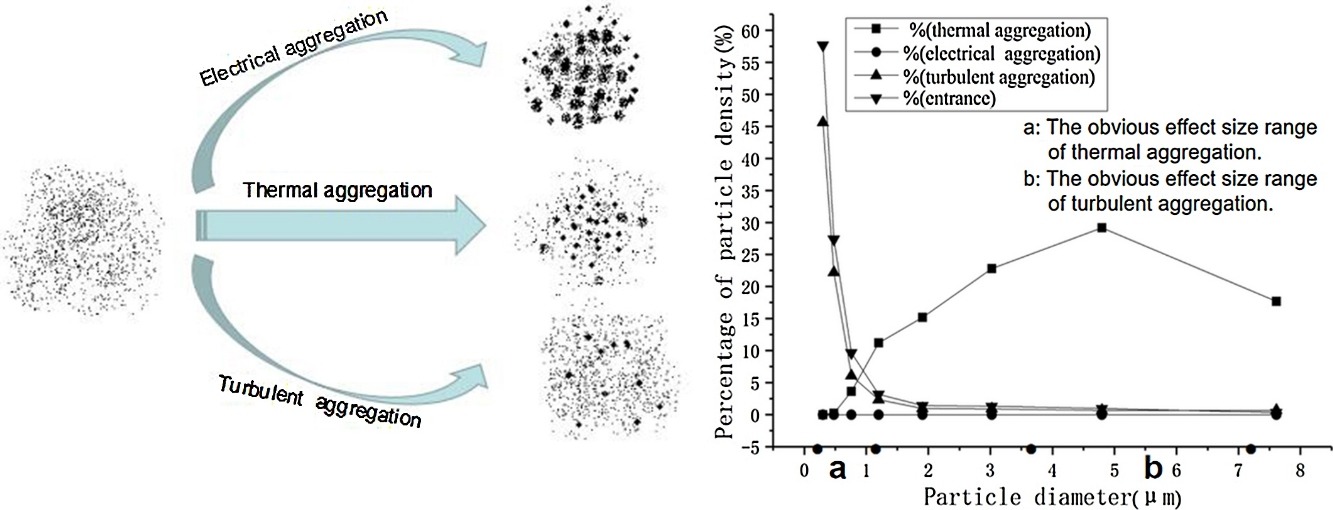

• A population balance model simulated particle aggregation in an electroprecipitator.

• Optimum conditions for particle aggregation effects were studied and determined.

• Electrical aggregation was evident for both micron- and submicron-sized particles.

• Particle aggregation was mainly determined by electrical aggregation.

Aggregation of fine ash into larger particles benefits fly ash removal in an electrostatic precipitator. Thermal aggregation, turbulent aggregation, and electrical aggregation of fine ash (derived from co-firing of biomass fuel and anthracite coal) was simulated under different conditions in an electrostatic precipitator. A population balance model and user-defined function in Fluent were assumed to obtain aggregation kernel functions and calculate the aggregation effects on the co-combusted particles. The results show that electrical aggregation had an obvious effect on both micron- and submicron-sized particles. For submicron particles, the effect of thermal aggregation is about ten times greater than turbulent aggregation. Meanwhile, for micron-sized particles, turbulent aggregation is about seven times greater than thermal aggregation. Therefore, particle aggregation in the electrostatic precipitator mainly occurs because of electrical aggregation, supplemented by thermal aggregation and turbulent aggregation. When the flow velocity is 1.0 m/s, particle volume fraction is 1.4%, and biomass co-firing ratio is 10%, the effects of all three aggregation processes on ash particles are optimized.