- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

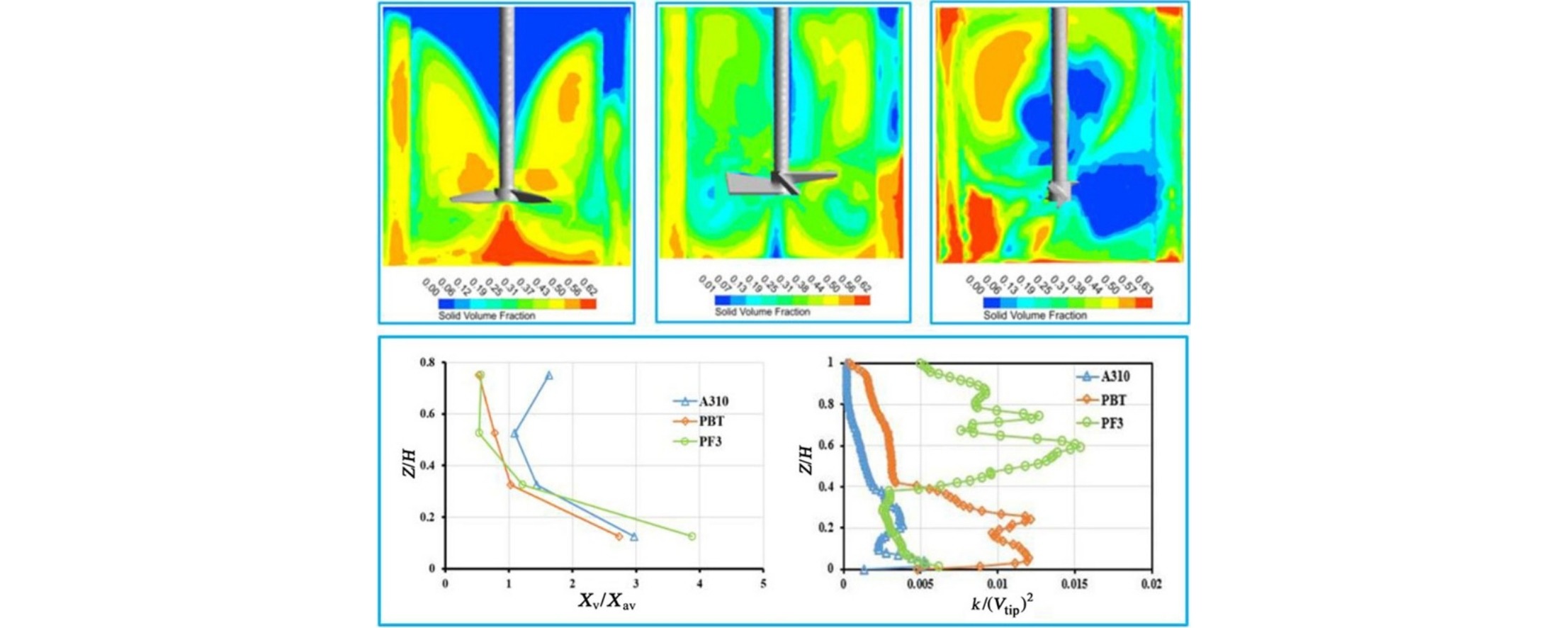

• Mixing of highly concentrated slurries was assessed for different impeller types.

• Performances of PBT, A310, and PF3 were analyzed using tomography.

• Solid particle distribution in the slurry tank was quantified using tomography.

• Velocity and turbulent kinetic energy profiles were found for all impellers.

• PBT was the most efficient impeller for mixing highly concentrated slurries.

Many chemical engineering processes deal with dense suspensions of large solid particles in liquid. Behaviors of such systems are difficult to predict because the many solid particles strongly affect the hydrodynamics produced by the impeller. The main objective was to assess the performances of the PBT, A310, and PF3 impellers in agitating highly concentrated slurries of large particles. Electrical resistance tomography was used to determine the degree of homogeneity and solid particle distribution within the slurry reactor. To gain more insight into the complex behavior of the flow inside the dense suspensions, computational fluid dynamics simulations were conducted using a Eulerian‒Eulerian multiphase model. Both qualitative and quantitative analyses were performed to obtain details on the dispersed solid phase distribution and its effect on the mixing quality. We found that the PBT impeller was the most efficient in terms of consuming power and generating velocity and turbulent kinetic energy within the mixing tank.