- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

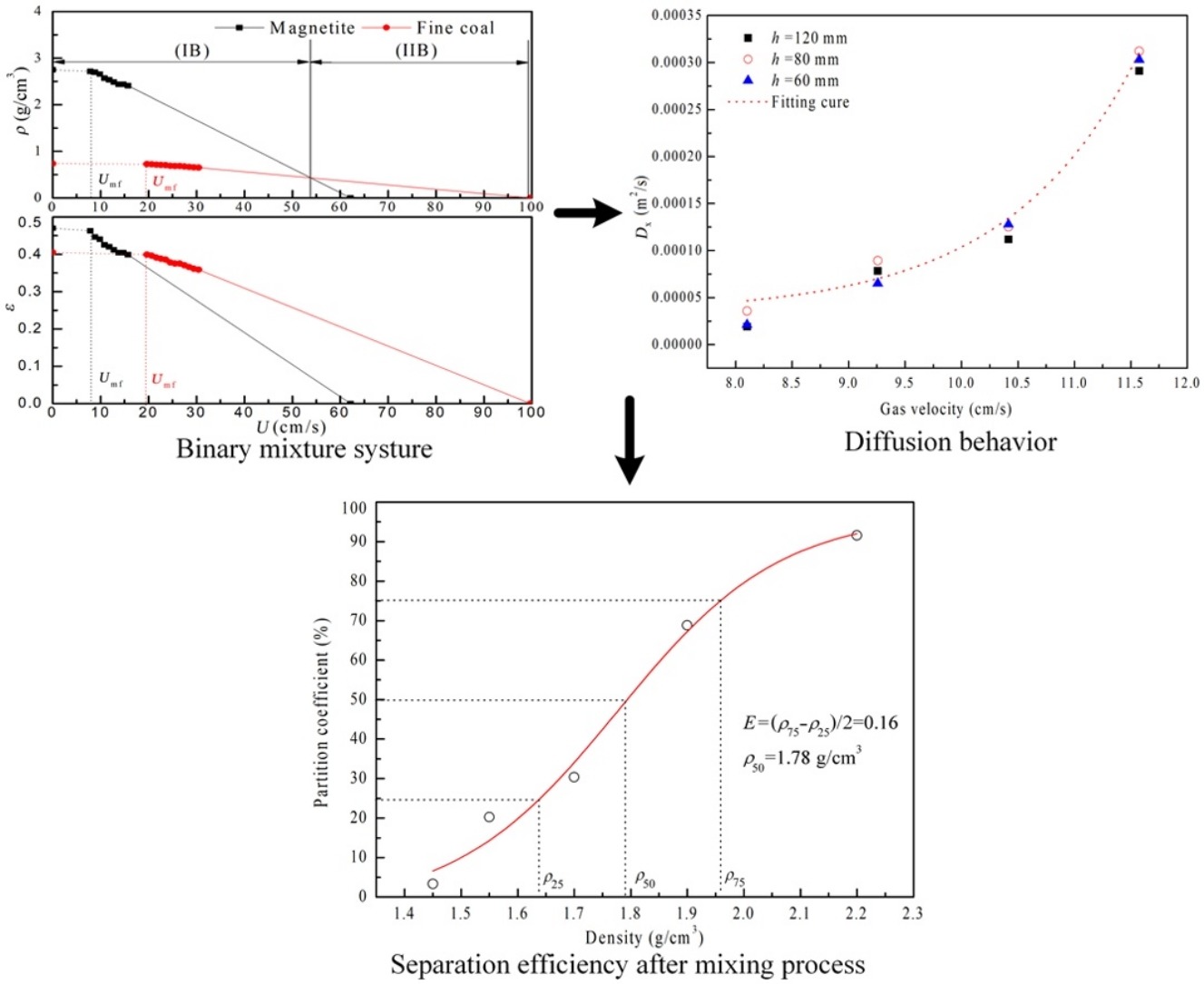

• A variety of particle mixture models were applied to binary mixtures.

• Particle mixing processes were studied with a white magnetite tracer.

• Two-dimensional mixing characteristics of fine coal are explained.

• Bed density was adjusted during the mixing process of fine coal.

• Effects of mixing processes on the separation performance were revealed.

In a gas–solid separation fluidized bed, mixing of fine coal is necessary to achieve a suitable bed density to enable effective separation of low rank coal. On the basis of a variety of mixture models, a gas–solid separation fluidized bed was judged, where fine coal particles of 0.6–1.0 mm were uniformly mixed with magnetite powder. High-speed dynamic camera technology was combined with a slump-sampling method to study the mixing process of the fine coal in the fluidized bed. These results showed that limitations of the fluidized bed structure cause the mixing process to be dominated by lateral diffusion and supplemented by axial diffusion. Axial diffusion was mainly achieved through the ascension of bubbles, whereas lateral diffusion was determined by the bursting action of the gas bubbles at the surface of the bed and the undulating characteristics of the bed. The effective lateral diffusion coefficient increased exponentially with gas velocity but had no strong relationship with the bed height. As the feed point moved toward the center, fine coal began to diffuse to both sides, which shortened the time for the bed density stabilization from 20 to 5 min. The bed density of the layer was stabilized at approximately 1.75 g/cm3. The separation efficiency of the gas–solid separation fluidized bed containing binary mixtures was more obvious for 6–50 mm raw coal, with a probable error E of 0.16.