- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

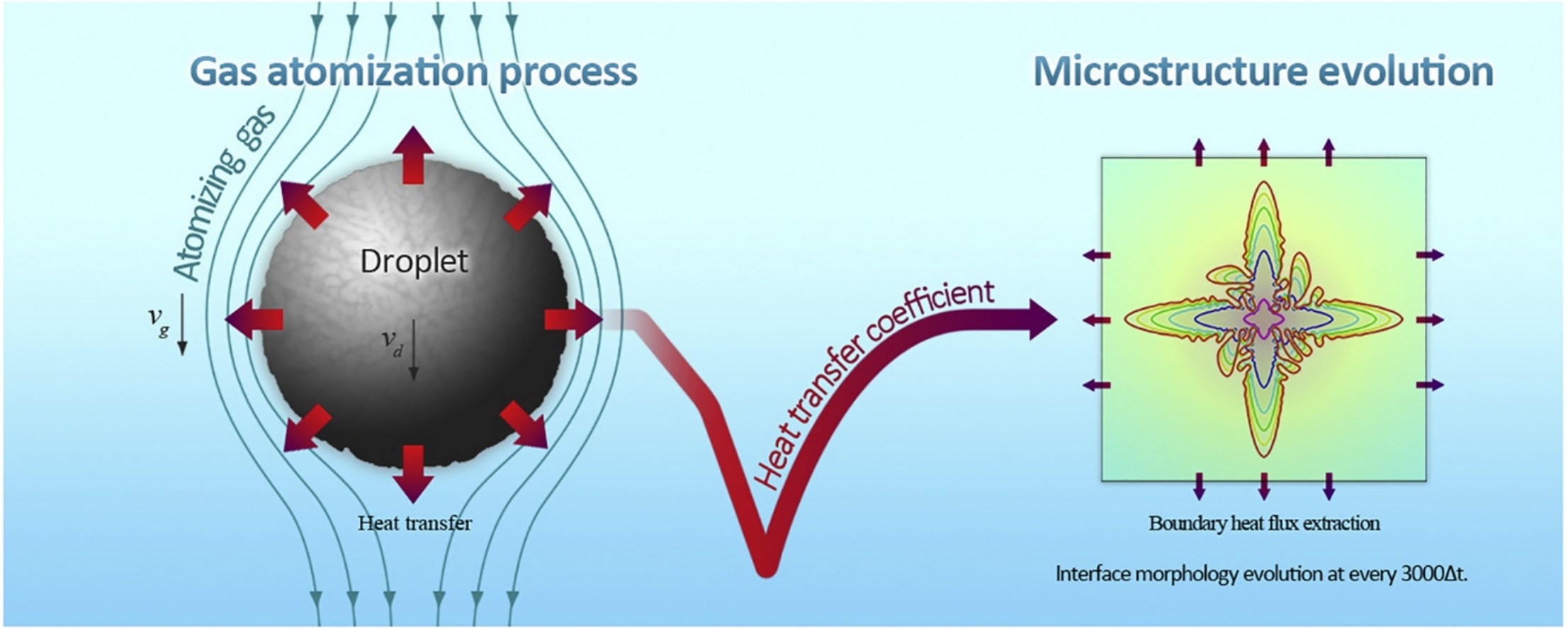

• The heat transfer process of an atomized droplet in flight was analyzed.

• A phase field model for gas atomized droplet solidification was established.

• Dendrite growth at different thermal boundary conditions was compared and analyzed.

Catalytic powders with fine microstructures can be produced from a rapidly solidified gas atomized Al–Ni alloy. The solidification microstructure of the droplets is closely linked with heat flow conditions. Thus, the heat transfer conditions between the gas and droplet are essential to microstructural evolution. In this study, a phase field model for simulating single and multiple dendrite growth in a binary Al–Ni alloy was constructed and the microstructural evolutions occurring during a gas atomization process were evaluated. Temporal variations in the heat transfer coefficient and the boundary heat flux were taken into account. The results revealed that the heat transfer coefficient of the atomized droplet in flight is correlated with the droplet size and the relative velocity between the droplet and the atomizing gas. During the simulation, the competition between boundary heat flux extraction and latent heat release from phase transition causes a recalescence process in thermal history, thereby affecting the gradient temperature distribution and, consequently, the dendrite morphology. Dendrite growth under the effects of the heat transfer coefficient is restrained continuously because of the decreasing amount of extraction. The computational results confirmed the fine homogeneous microstructure and low microsegregation levels of gas atomized powders.