- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

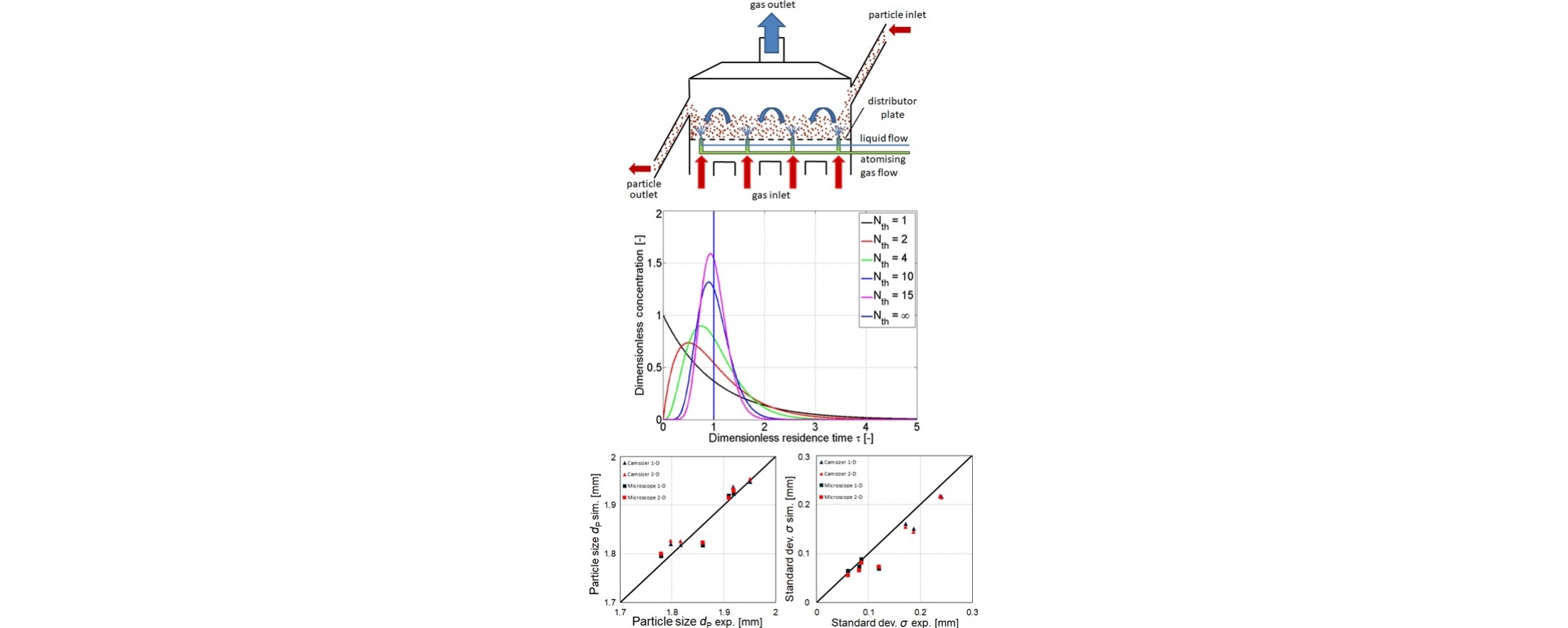

• Horizontal fluidized-bed coating experiments.

• Analysis of particle size and layer-thickness distributions.

• Simulation of coating process, using population-balance equations.

• Good agreement of experimental and simulated particle-size distributions.

• Fair agreement of experimental and simulated layer-thickness distributions.

To predict the particle size and layer-thickness distributions (LTDs) in a continuously operated horizontal fluidized-bed granulation process, two alternative models were considered. A one-dimensional two-zone model was proposed, which describes with population-balance equations the particle growth in a spraying zone that is separated from the drying zone. The residence-time distribution (RTD) was calculated from a literature correlation and was coupled with a population-balance model via a tank-in-series model with reflux. A two-dimensional, one-zone population-balance model, which was based directly on the RTD and the feed particle-size distribution (PSD) was also used. Granulation experiments were conducted and analyzed microscopically and with a camera optical device to determine the sample PSDs. LTDs over the particle population were derived from the PSDs and were analyzed directly by micro-computer-tomography. To compare the simulated data with the experimentally determined distributions, the PSDs were converted to LTDs. The good agreement shows that both methods are suitable to determine the PSD from an RTD of an arbitrary granulation process in a horizontal fluidized bed. Improvement appears necessary with regards to the LTD spread.