- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

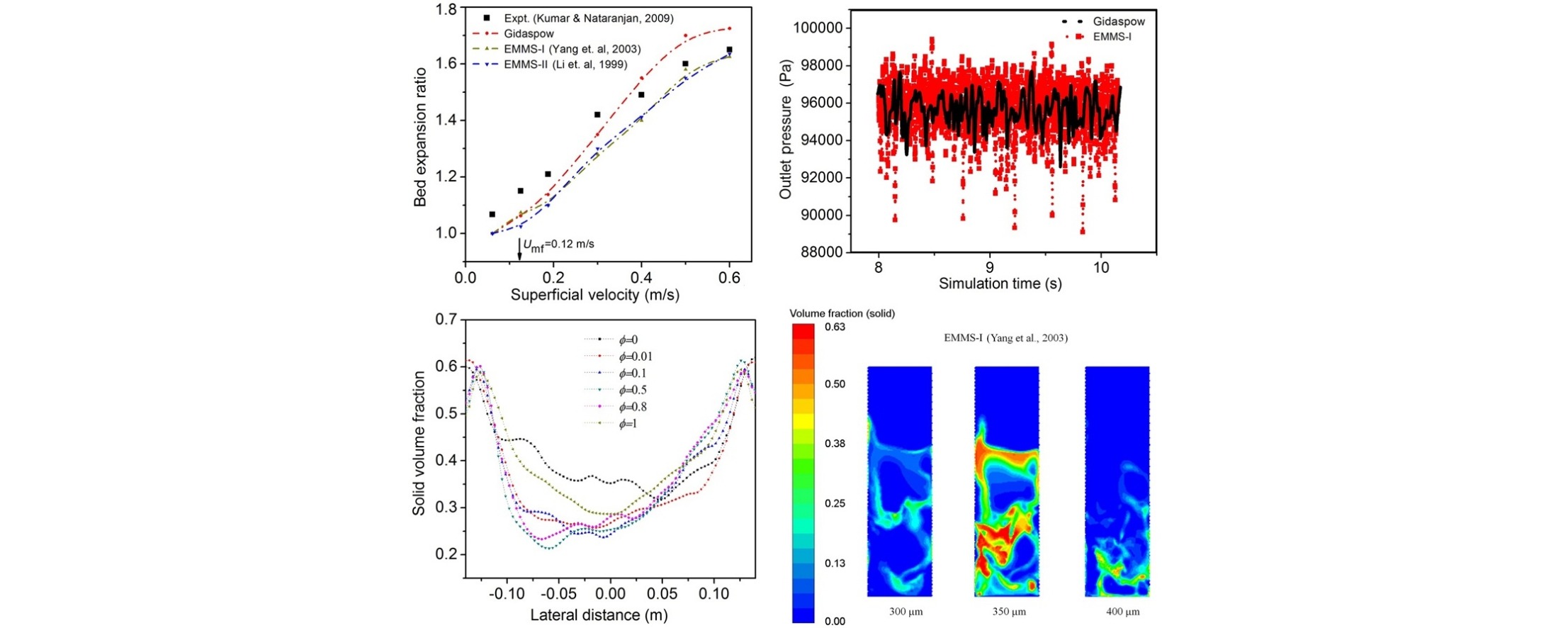

• Gas–solid fluidized bed of Geldart B particles is modeled using CFD.

• Predictions of heterogeneous EMMS and homogenous Gidaspow drag models are compared.

• Effects of restitution and specularity coefficients are examined.

• Vertical segregation is simulated for differently sized solids in a bed.

• Polysilicon FBR is simulated using both Gidaspow and EMMS drag models.

The energy minimization multi-scale (EMMS) is a heterogeneous drag model widely used to simulate gas–solid fluidized beds. In this work, we conducted computational fluid dynamics simulations of a gas–solid fluidized bed for Geldart B particles to compare the EMMS with the homogeneous Gidaspow drag model. The results from both the homogeneous and heterogeneous drag models were compared with literature experimental data on pressure drop and bed expansion. There was no noticeable difference in predicted bed characteristics in the slugging regime. However, in the turbulent regime, the EMMS model predicted slightly lower bed expansion than did the Gidaspow model. We evaluated the effects of solid–solid and solid–wall interaction parameters by varying the restitution and specularity coefficients. Bed expansion increases by a factor of 1.05–1.08 when the restitution coefficient increases from 0.9 to 0.99. The models predict a higher solid volume fraction and higher solid downflow velocity near the wall for a low specularity coefficient of 0.01 or 0. When we considered solid phases of different sizes to model polydisperity, the simulation predicted vertical segregation of 300, 350, and 400 μm in the fluidized region due to gravity. Furthermore, the drag models made similar predictions in bad characteristics from cold model simulation of a polysilicon fluidized-bed reactor, although there was very little vertical segregation of solid particles for this case.