- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

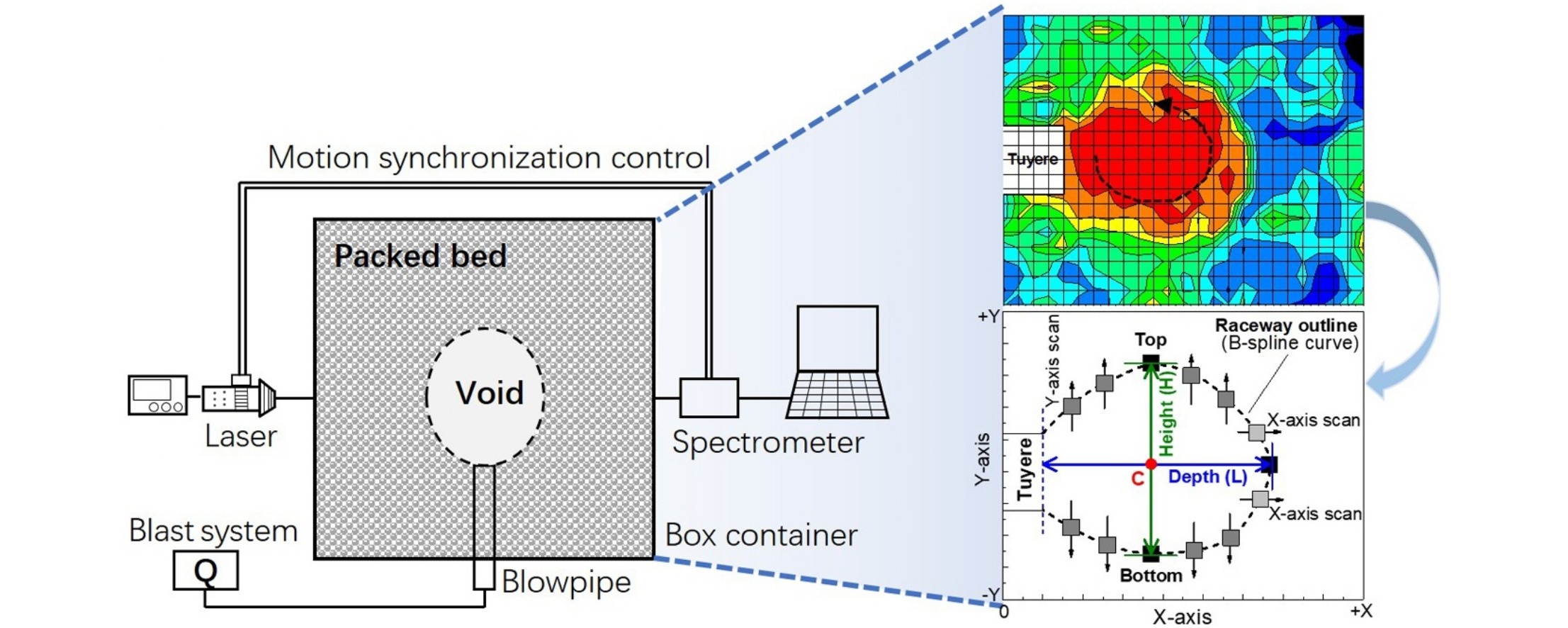

• Void boundaries in 3D packed beds are determined via a novel optical method.

• The voids are ellipsoid and their shapes and locations are relatively stable.

• The effects of the blast and the geometric parameters on the void are analyzed.

• Laser attenuation measurements can determine void boundaries in small cold models.

Voids are important regions in some industrial processes, particularly in the iron-making process, because a void is a zone in which gas–solid heat transfer and reactions occur. This paper presents a 3D experimental study of void formation measurement with 2D projection in a packed bed using an optical method. By developing an experimental laser-attenuation scanning method, invisible voids that form in a packed bed can be detected and identified as relatively stable ellipsoids. The effects of various operational parameters on void formation are analyzed in terms of the resulting void sizes and shapes. The results show that the void shape that forms in the packed bed is close to an ellipsoid and is relatively stable. The void size is positively correlated with the blast volume rate and is negatively correlated with the blowpipe diameter. The blowpipe depth has no significant effect on either the void formation or size. The blast angle affects the void location strongly; when this angle is increased, the void moves upward. The information and methods obtained in this experiment are significant in aiding understanding of the mechanism of void formation in gas–solid reactors.