- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

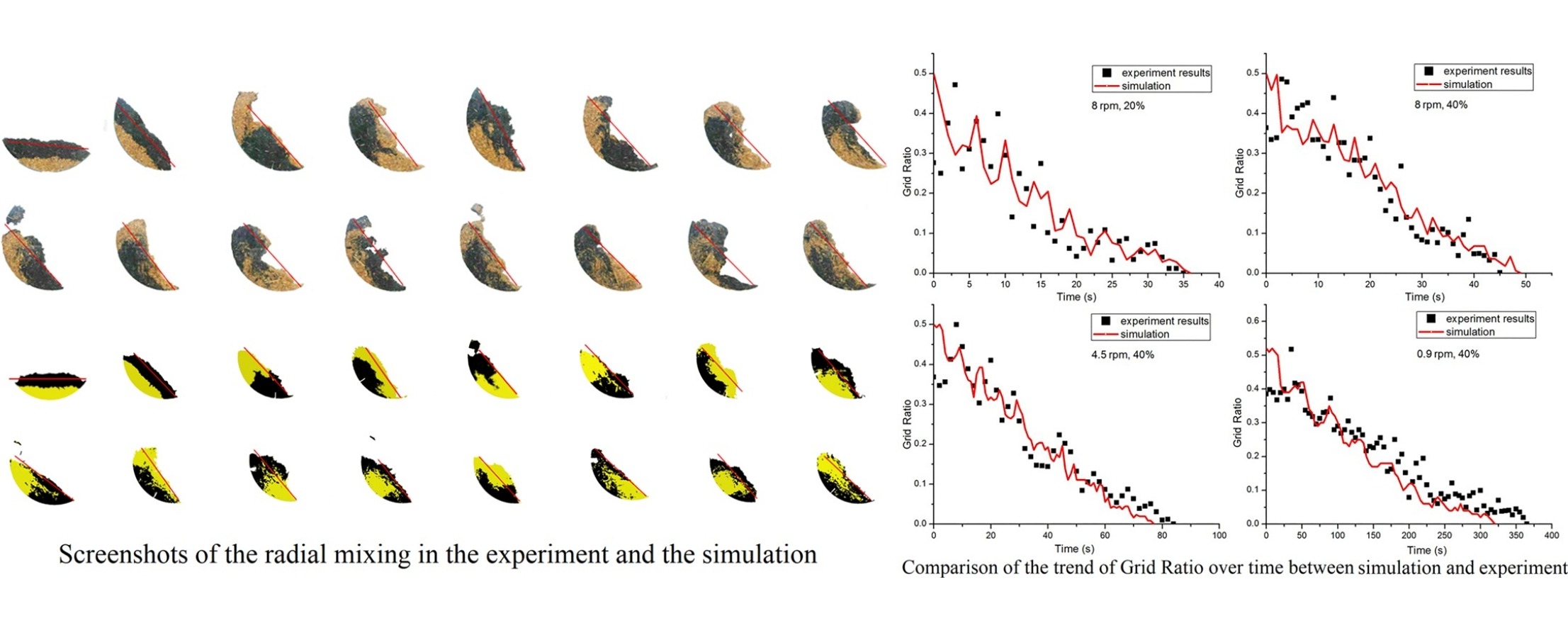

• Established rod-shaped particle model for sweet sorghum particle.

• Influence of particle shape and size on particle packing was investigated.

• Orthogonal method used to determine main factors and optimum level.

• Simulated results agreed well with experimental data.

The mixing of raw materials in a rotary drum bioreactor is important for advanced solid-state fermentation technology. However, the shape, size, and other properties of pulverized sweet sorghum stalk particles are more complicated than those of the spherical particles. In this study, a soft rod-shaped discrete particle model was established and verified to simulate the mixing behavior of sweet sorghum stalk particles in a rotary drum bioreactor. We were inspired by the particle shape and established a rod-shaped particle model by investigating the influence of the shape (length–diameter ratio) and size (diameter) on the particle packing (stack height and bed porosity). We used orthogonal simulations and extremum difference analysis to determine the main factors, optimum level, and groups of other parameters. Based on calibrated parameters, twelve sets of simulations of radial mixing in the drum were performed, and the results were compared with experiments conducted under identical operating conditions. The average relative error between the simulation and the experiment was 10.95%, which indicates that they agreed well and that the simulation could predict the mixing process well.