- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

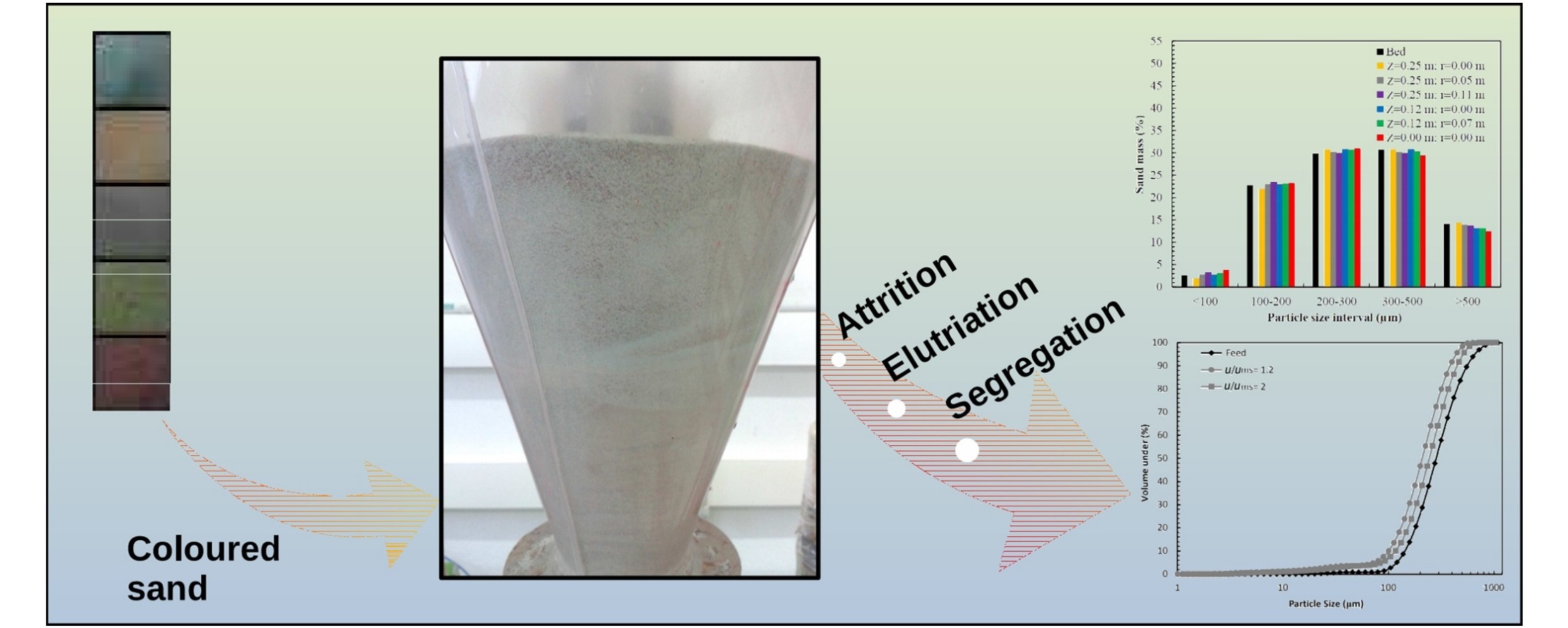

• Particle elutriation, attrition and segregation were studied.

• A new methodology based on colouring and local monitoring of fractions is proposed.

• Breakage is responsible for the majority of particle attrition.

• Elutriation is dramatically reduced by adding a fountain confiner.

• A fountain confiner minimizes both elutriation and segregation.

This study examined elutriation, attrition, and segregation in a conical spouted bed with a fountain confiner and incorporating an open sided draft tube. Fine silica sand with a wide particle size distribution was employed as a model material, operating in both the batch and continuous modes. The use of a fountain confiner is crucial when operating with fine particles, because otherwise the bed rapidly exhibits significant entrainment. The extent of attrition was quantified using a tracing technique based on differently-coloured sand fractions as well as monitoring size distributions by sieving. Particle breakage was found to be the primary attrition mechanism, and the fountain confiner was determined to limit the elutriation of fine particles resulting from breakage. Consequently, only a small fraction of the finest particles were entrained from the bed. The incorporation of a confiner increased operational stability while reducing segregation, especially in the upper half of the bed where the majority of segregation typically occurs. Thus, the bed was perfectly mixed apart from very minimal segregation close to the wall and at the bottom of the contactor. These results provide a basis for the design and operation of larger scale equipment for the continuous drying of materials.