- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Polyphenolic extracts are directly applied in spouted-bed encapsulation.

• A batch spouted-bed process is used for the encapsulation.

• Active constituents are quantitatively transferred from the extracts into particles.

• Maltodextrin with dextrose equivalent 6 is sufficient as a sole carrier and shell material.

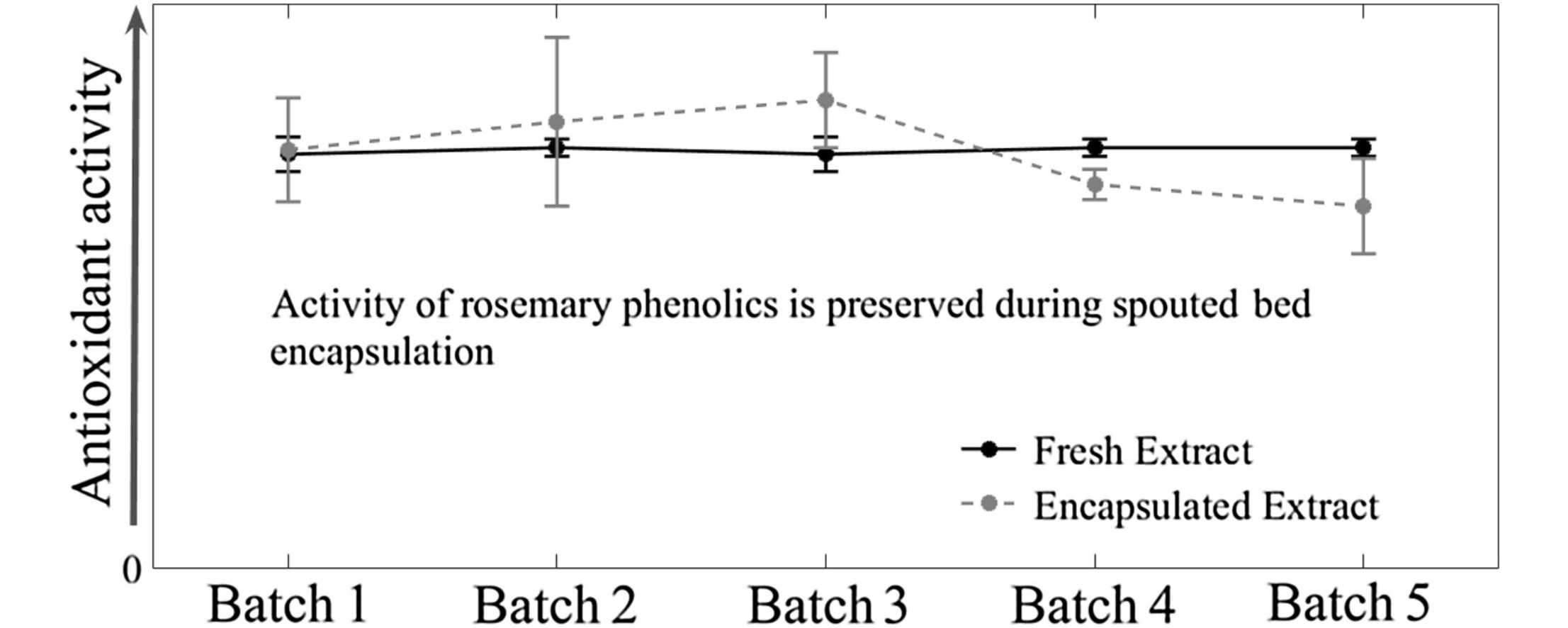

In this study, spouted bed technology was applied to the protection and functionalization of polyphenolic rosemary extracts. First, solid–liquid extraction was performed at 25 °C with ethanol–water. The ethanol–water ratio was chosen to obtain high phenolic acid and diterpene concentrations in the extract. The selected solvent composition gave liquid extracts that could be directly added to a coating mixture for feeding into a spouted bed apparatus. Thus, no preliminary solvent exchange or evaporation of the extraction solvent to dryness was required. Food grade Paselli MD 6 maltodextrin and HiCap 100 modified starch were used as inert core and shell materials in the spouted bed encapsulation process under mild operating conditions. The antioxidant activity of the fresh extract was retained during processing, which indicated that the active constituents were preserved and quantitatively transferred into the encapsulated formulations, which were readily soluble in water. The obtained powders were composed of nearly spherical particles. Their compositions, water solubilities, and particle morphologies make them a strong candidate for food and beverage applications as natural antioxidants, preservatives, or functional ingredients.