- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

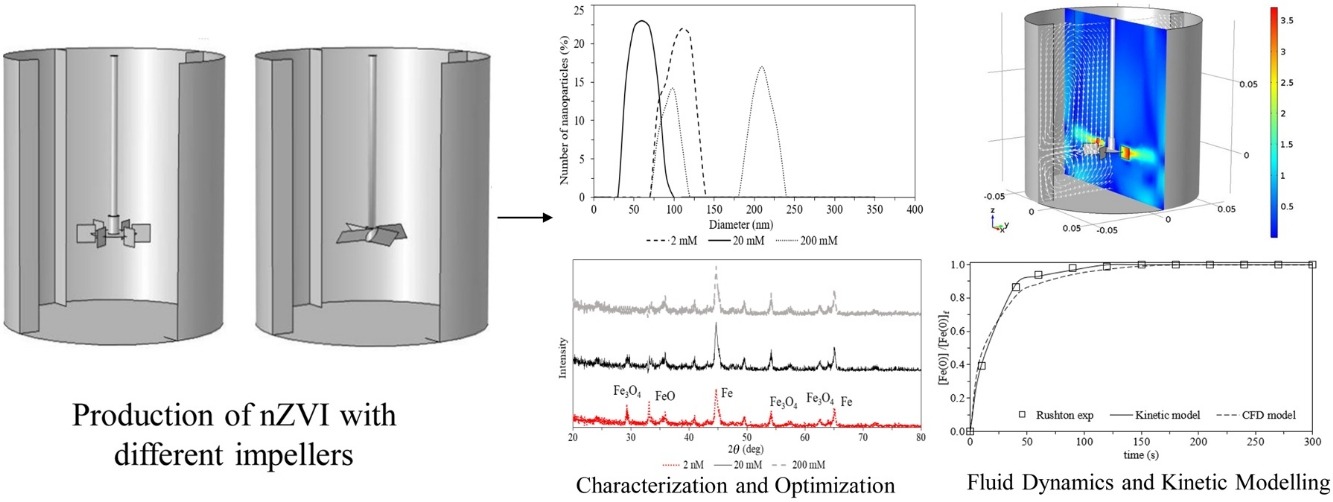

• nZVI particles were synthesized with both radial and mixed flow impellers.

• The synthesis was successfully described as pseudo-nth-order kinetic.

• A unimodal particle size distribution was achieved via process optimization.

• The optimized production was characterized by a mean particle size of 40 nm.

• The calculated mixing Damkohler number indicated a mixed control process.

The aim of this work is to optimize iron nanoparticle production in stirred tank reactors equipped with two classical impellers: Rushton and four-pitched blade turbines, which are largely used in batch industrial synthesis and efficient scale-up. The main operative parameters of nanoparticle synthesis are the precursor initial concentration, reducing agent/precursor molar ratio, impeller–tank clearance, and impeller rotational velocity. These parameters were varied during the synthesis to find the optimal operating values based on the Fe(0) (%) production, zeta potential, particle size distribution, and powder X-ray diffraction pattern obtained. We found that the optimal operating conditions for nanoparticle production were an impeller velocity of 1500 rpm, initial iron precursor concentration of 20 mM, molar ratio of reducing agent to iron precursor of 3 mol/mol, and impeller clearance of 0.25 and 0.4 times the vessel diameter for Rushton and four-pitched blade impellers, respectively. Setting these conditions achieved a total conversion of 0.94–0.98 and yielded a product with a unimodal size distribution and average diameters in the range 30–50 nm. The computational fluid dynamics results agreed with the expectations, and the obtained mixing Damkohler numbers show that the process is mixed controlled.