- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

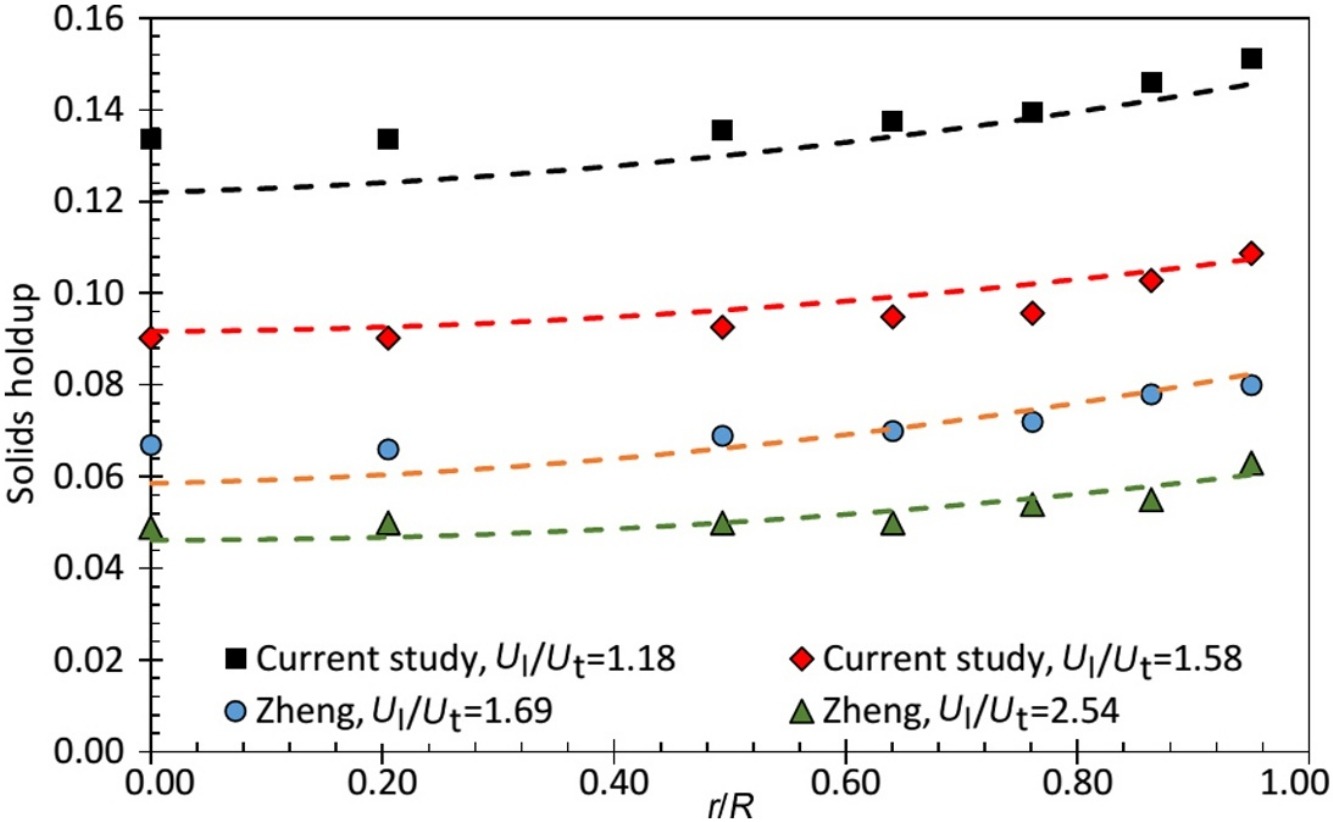

• Model validated by comparing model predicted and pilot-scale LSCFB data.

• GP model prediction and experimental data are in agreement.

• Statistical performance measures of the GP model are quite competitive.

• Three different scales are compared with experiments for model validation.

• Different parameters are considered for comparing scale-up effects.

Understanding scale-up effects on the hydrodynamics of a liquid‒solid circulating fluidized bed (LSCFB) unit requires both experimental and theoretical analysis. We implement multigene genetic programming (MGGP) to investigate the solid holdup and distribution in three LSCFB systems with different heights. In addition to data obtained here, we also use a portion of data sets of LSCFB systems developed by Zheng (1999) and Liang et al. (1996). Model predictions are in good agreement with the experimental data in both radial and axial directions and at different normalized superficial liquid and solid velocities. The radial profiles of the solid holdup are approximately identical at a fixed average cross-sectional solid holdup for the three LSCFB systems studied. Statistical performance indicators including the mean absolute percentage error (6.19%) and correlation coefficient (0.985) are within an acceptable range. The results suggest that a MGGP modeling approach is suitable for predicting the solid holdup and distribution of a scaled-up LSCFB system.