- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

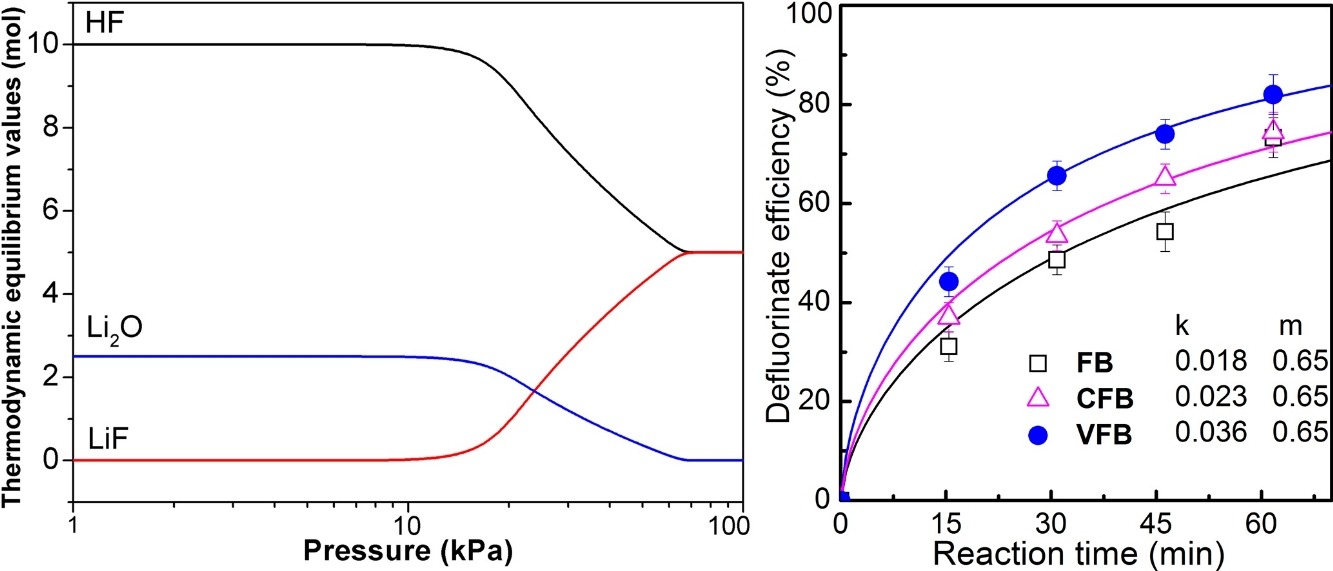

• Vacuum fluidized bed (VFB) improved the defluorination efficiency of lepidolite particles.

• The improvement is attributed to the increase of the H2O/HF ratio in VFB.

• The VFB has a higher defluorination efficiency than a conventional reactor.

• Consumption of steam is greatly reduced by addition of coal char.

• The VFB roasting method is promising for the treatment of lithium ores.

Defluorination roasting of lepidolite ore in a fluidized bed reactor has been proposed for improving the extraction efficiency of lithium. In this paper, a vacuum was introduced to the fluidized bed reactor, which significantly improved the defluorination efficiency of lepidolite particles. This improvement could be attributed to an increase in the H2O/HF ratio. The highest defluorination rate for the lepidolite particles was obtained in the fluidized bed reactor under vacuum. The rate in the vacuum reactor was 1.5–2 times that in a fixed bed reactor or conventional fluidized bed reactor. The defluorination efficiency of the lepidolite particles also improved and the consumption of steam was greatly reduced by addition of coal char. This enhancement was mainly attributed to changes in the structures of the reduced lepidolite particles. This defluorination roasting method for high lithium extraction with low water steam consumption is a promising method for lithium ore treatment.