- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

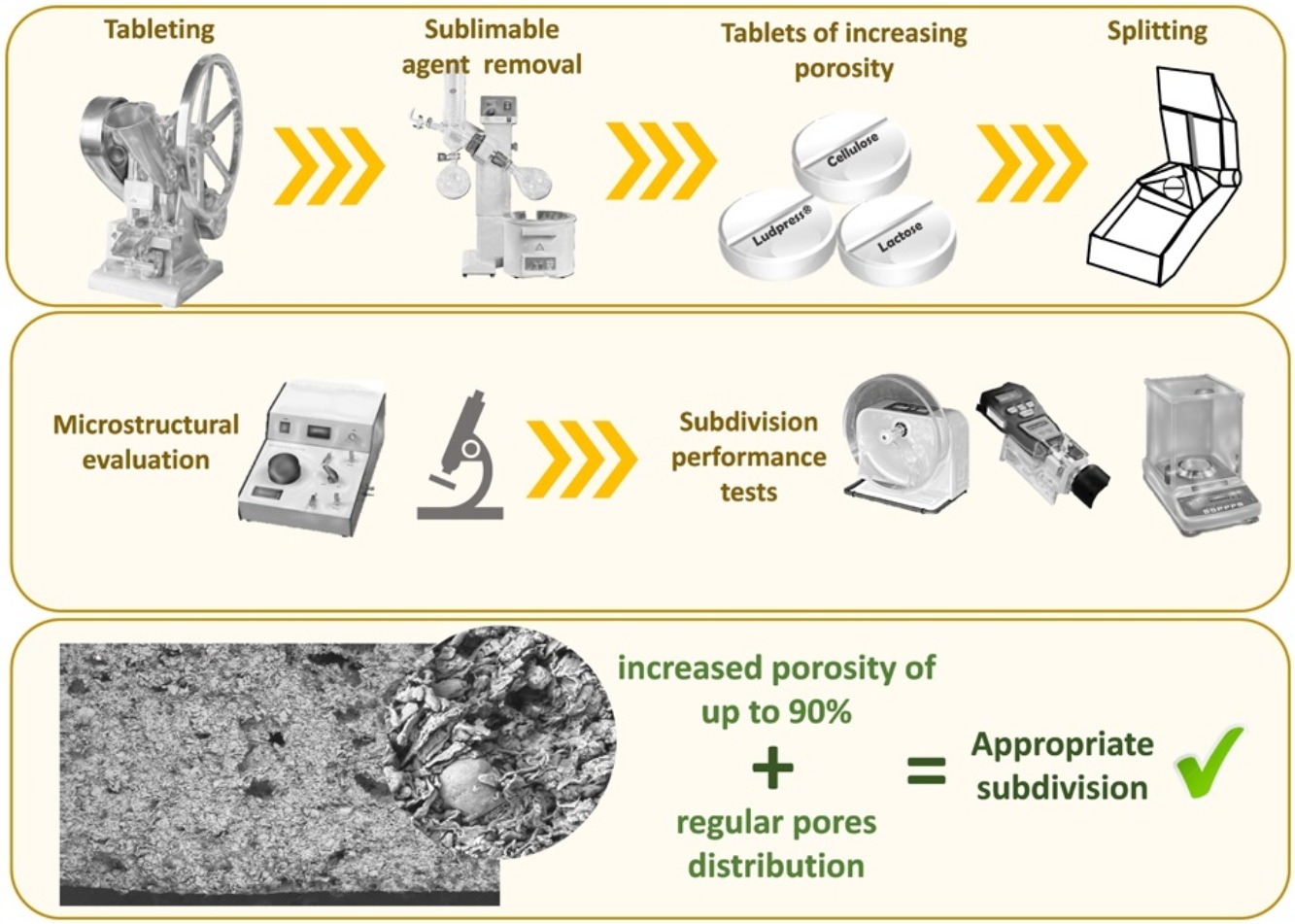

• Tablets of increasing porosity were achieved in the presence of a sublimable agent.

• A tablet porosity >90% led to inadequate subdivision outcomes.

• Irregular pore size distribution resulted in subdivision failure.

• Tablets having a subdivision purpose should have controlled porosity.

A tablet microstructure, especially the porosity, is a crucial parameter that influences the mechanical properties. Herein, tablet subdivisions were studied as a function of tablet porosity. The tablets were manufactured in the presence of different diluents, namely microcrystalline cellulose, Ludipress®, or lactose monohydrate. Furthermore, the addition of Camphor was investigated, which was thereafter sublimated with a view of obtaining tablets having varying degrees of porosity. Microstructural assays were correlated to the subdivision performance. The increase in porosity reduced the hardness and increased the tablet friability, adversely impacting the subdivision. For all the excipients, an increase in relative porosity >90% represented the threshold level from which an inadequate subdivision occurred. The increase in tablet porosity led to a reduction in mechanical resistance, which, combined with a heterogeneous and discontinuous distribution of pores within the matrix, resulted in poor subdivision results. Controlling tablet porosity is an important consideration when designing tablets having a subdivision purpose.