- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• The Taguchi method was used to evaluate granule strength during iron ore sintering.

• The moisture, hydrated lime, and magnetite concentrate contents were varied.

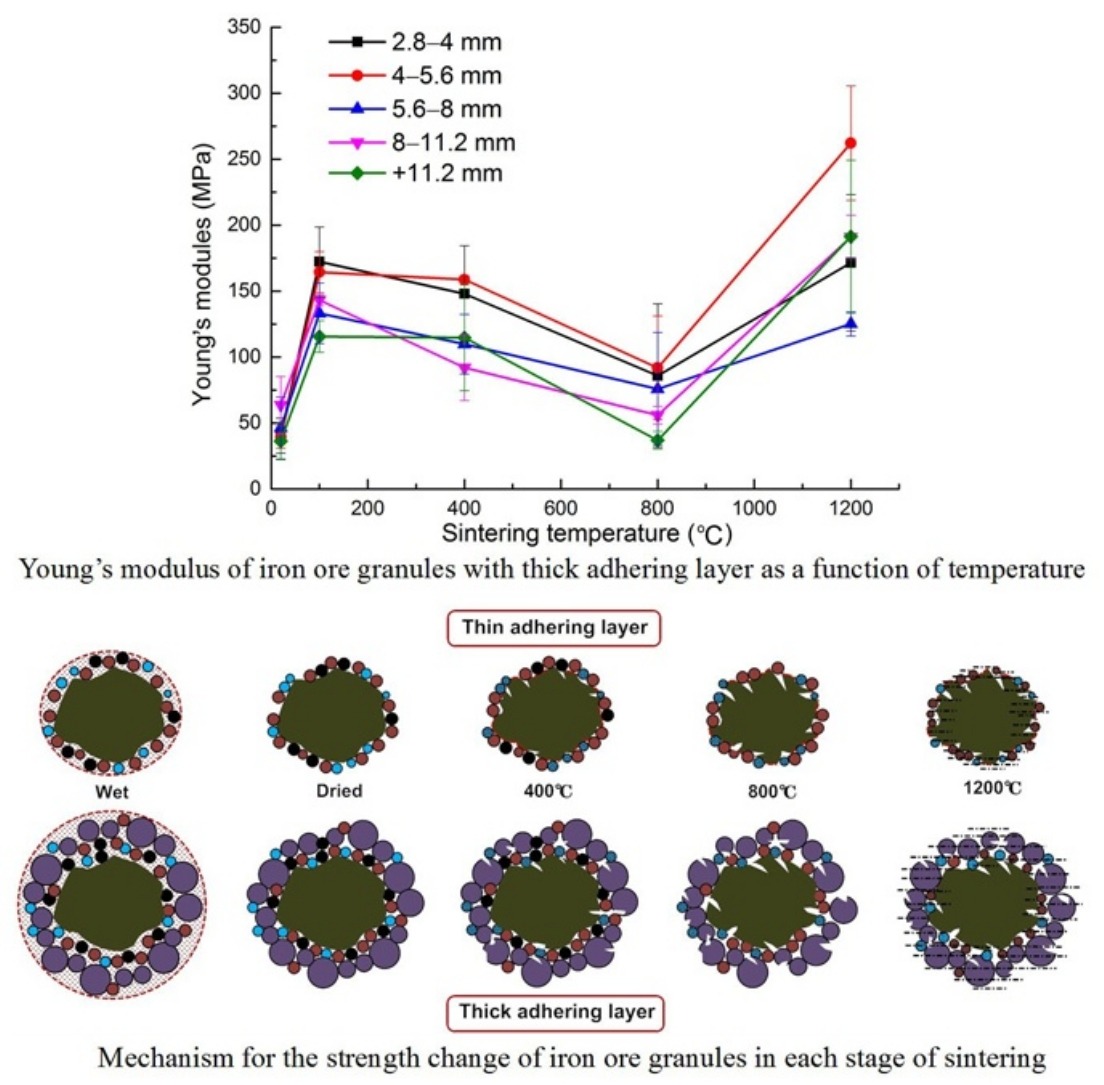

• The crushing strength and Young’s modulus of granules during sintering were measured.

• The relationship between granule structure and strength properties was elucidated.

• The contribution of each operating parameter to granule strength was estimated.

The contributions of three operating parameters (moisture content, hydrated lime addition, magnetite concentrate substitution) to the crushing strength and Young’s modulus of granules in each stage of iron ore sintering were studied by applying the Taguchi method. The results indicated that the strength properties of the iron ore granules were greatly affected by its structure, which is composed of inner nuclei and an outer adhering layer. The granules with a thick adhering layer showed a clear changing trend in strength with increasing temperature, whereas those with a thin adhering layer showed additional fluctuations as their force–displacement responses were greatly determined by the nuclei. The granules with a thick adhering layer were generally more deformable and easier to break than that those with the thin adhering layer in most states. The signal-to-noise ratio and variance analysis indicated that moisture was the dominant parameter affecting the strength properties of the iron ore granules, as this factor controls the primary granule structure and material distribution. With the progress of sintering, the contribution of moisture to the quality characteristics gradually decreased (from ∼80% to 50%), whereas the contributions of hydrated lime and magnetite concentrate increased correspondingly (from ∼5% to 20%).