- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

Xiao Zhu, Xuan Feng, Yuanyuan Zou, Laihong Shen *

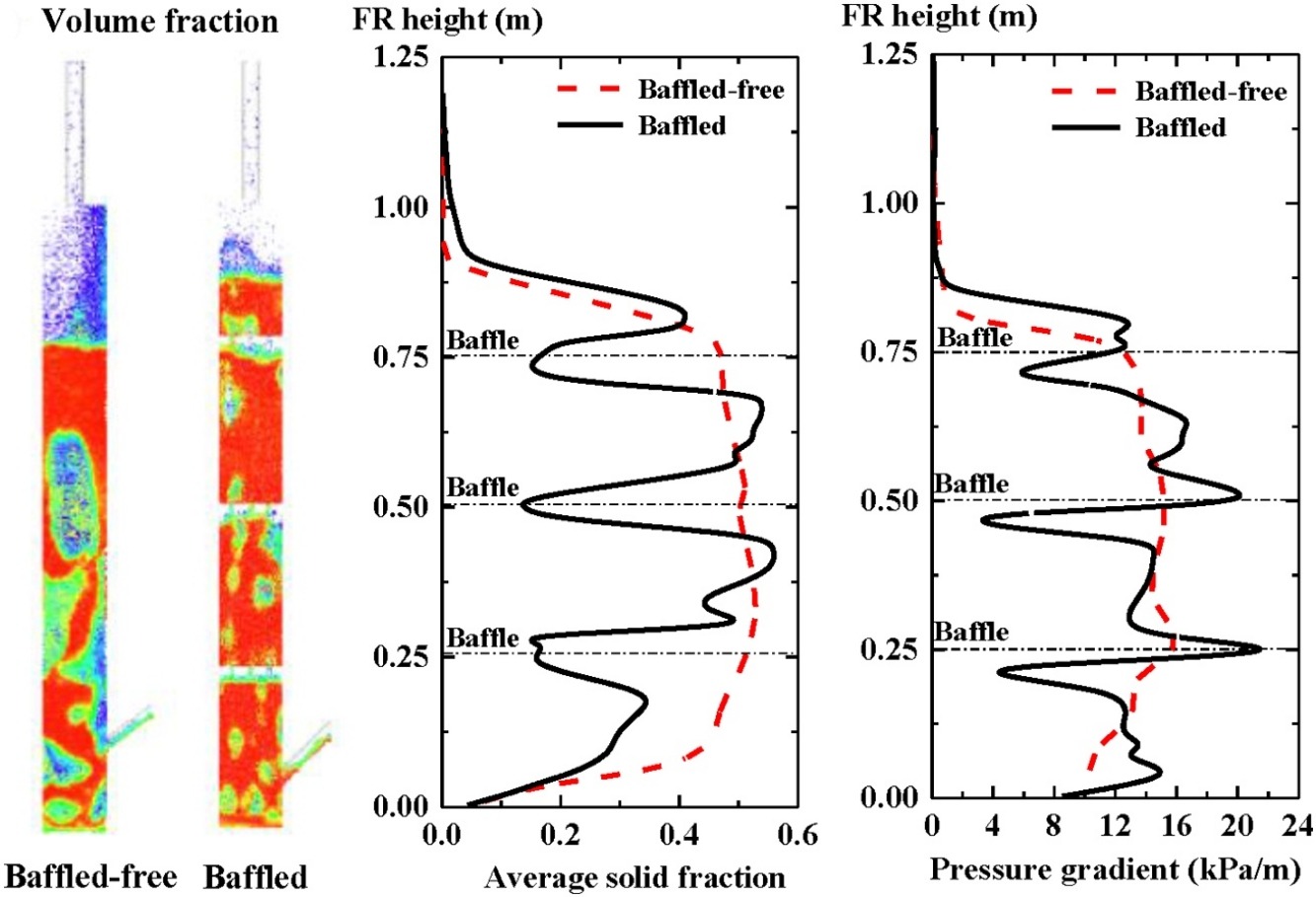

• Baffles in a bubbling fluidized bed broke up bubbles and improved gas–solid contact.

• A fluidized bed model was simulated based on experimental results.

• The bubble properties, gas–solid distribution, and pressure gradient were analyzed.

• The effects of baffle number and opening ratio were studied.

A bubbling fluidized bed is generally used as the fuel reactor in chemical looping processes. However, insufficient gas–solid contact remains a steadfast problem. As such, we propose the use of internal baffles to split bubbles at a high gas velocity and to restrict the movement of large-scale solids in the fluidized bed. We investigated the effect of baffle arrangement on the bubble size and energy, pressure gradient, particle distribution, and particle velocity in a fluidized bed using a computational particle fluid dynamics simulation based on our experimental results. We discuss the main influencing factors, which include presence of caps, number of baffles, and the baffle opening ratio. The baffle structure with caps efficiently broke the large bubbles without creating jet flow. Three baffles were deemed suitable in the bed owing to the small bubble size and uniform gas–solid distribution in each compartment. We selected a baffle opening ratio of 20.5%, which improved the flow pattern without causing a significant increase in the pressure gradient and particle velocity through the baffles. We also discussed the potential for scaling up this baffled fluidized bed for industrial applications.